7 Unmatched Advantages of 3D Printing (Outpace Competitors in Every Industry)

In the manufacturing industry, companies are constantly searching for ways to stay ahead. One major hurdle many face is the slow pace of traditional manufacturing and design processes.

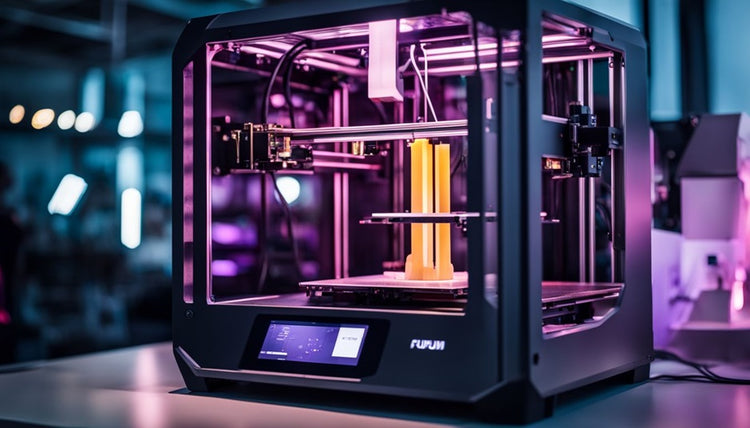

This can hold back product development and market responsiveness. 3D printing, or additive manufacturing, stands out as a game-changing solution that addresses these challenges head-on by offering speed, efficiency, and flexibility.

One key advantage of 3D printing is its ability to produce strong yet lightweight parts quickly and cost-effectively. This breakthrough technology accelerates the design process and significantly reduces waste, making it both an economical and eco-friendly option.

From aerospace to automotive industries, businesses leveraging 3D printing can enjoy a significant competitive edge.

This article digs into five unmatched benefits of this revolutionary approach that will help you outpace competitors across any industry.

Get ready for insights that could transform your business!

Key Takeaways

- 3D printing makes designing faster and cheaper by letting people try out new ideas quickly.

- It enables companies to produce only what's needed when it’s needed, cutting down on waste and saving money.

- This technology helps create unique products for customers’ exact needs, offering more flexibility in design.

- Businesses can speed up the process from idea to finished product, helping them stay ahead of competitors.

- 3D printing is better for the environment because it uses less material and produces fewer items that might not get sold.

Advantages of 3D Printing for Businesses

#1 Simplified design process

3D printing transforms the way companies approach design. This innovative technology allows for flexibility in design, making it easier to create custom solutions. Designers can experiment with complex shapes and structures without worrying about the limitations of traditional manufacturing methods.

The process becomes more straightforward, empowering engineers, architects, dentists, and automotive industry professionals to turn their ideas into reality quickly.

The ability to tweak designs on the fly significantly cuts down development time. As a result, businesses can iterate faster and more efficiently than ever before. This streamlined workflow boosts productivity and enhances the quality of the final product.

With 3D printing, achieving precision and customization in designs becomes both achievable and cost-effective, setting new standards in various industries.

#2 Faster prototyping and design

Transitioning from simplified design to faster prototyping and design, 3D printing accelerates the process of creating prototypes and designs. Companies can swiftly test new ideas, reducing time-to-market and gaining a competitive edge.

For instance, in the automotive industry, 3D printing allows for rapid prototyping of lightweight and strong parts, enabling swift innovation in vehicle design. In architecture, engineers use 3D printing to quickly prototype complex structures with minimal waste.

This speed in production and testing propels industries towards greater efficiency and innovation.

#3 Just-in-time manufacturing

3D printing allows for just-in-time manufacturing, enabling businesses to produce items precisely when needed. This reduces inventory costs and waste by only creating products as demand arises.

The flexibility of 3D printing technology makes sure companies can quickly respond to market changes and customer demands, staying ahead of the curve in a fast-paced industry landscape.

This approach corroborates with the rapidly evolving needs of various industries and provides a distinct competitive edge, enhancing productivity levels within diverse sectors such as aerospace, automotive, consumer goods production, and beyond.

With just-in-time manufacturing using 3D printing technology, companies can align their production activities with actual market requirements while reducing excess stockpiles. This propels them towards achieving greater efficiency and optimizing their resources.

#4 Flexible solutions

Create unique products tailored to specific customer needs with highly flexible and customizable designs. 3D printing enables companies to adapt designs in response to changing requirements, giving them a competitive edge in meeting diverse market demands.

This level of flexibility also allows for easier iteration and improvement based on real-world feedback, ensuring that the final product matches or exceeds customer expectations.

#5 Faster innovation and time-to-market

Businesses can swiftly innovate and introduce new products with 3D printing technology, thus gaining a competitive edge. This rapid innovation accelerates the time-to-market, enabling companies to meet consumer demand and stay ahead of competitors across diverse industries.

#6 Cost-effective manufacturing

3D printing offers a cost-effective manufacturing solution, saving companies money on tooling and production costs. It minimizes waste by using only necessary materials, reducing environmental impact and production expenses.

This revolutionizes industries like aerospace, consumer goods, and medicine, providing competitive advantages and driving innovation in a highly efficient manner.

#7 Eco-friendly and sustainable processes

Transitioning from cost-effective manufacturing to eco-friendly and sustainable processes, 3D printing technology minimizes waste by using only necessary materials, reducing environmental impact and production costs.

It offers a more sustainable approach to manufacturing, aligning with the growing global focus on eco-friendly solutions. With 3D printing, companies can significantly reduce their carbon footprint while producing high-quality products – a critical aspect in today's ever-evolving realm of sustainability.

Wrapping Up

These unmatched advantages of 3D printing can revolutionize industries and outpace competitors. The technology allows for flexible design, rapid prototyping, on-demand production, and strong lightweight parts.

3D printing streamlines the design and production process, leading to faster time-to-market and cost-effective manufacturing. Companies can reduce waste while creating bespoke products tailored to specific needs.

This practical approach enhances productivity and sustainability across various industries - an opportunity not to be missed!