When the Indian Army approached Think Robotics with a critical challenge, developing a portable, field-deployable oxygen generation system for high-altitude operations, the project requirements went far beyond standard engineering. The system needed to operate reliably in extreme conditions, meet stringent military specifications, and provide medical-grade oxygen purity in environments where traditional supply chains become impossible.

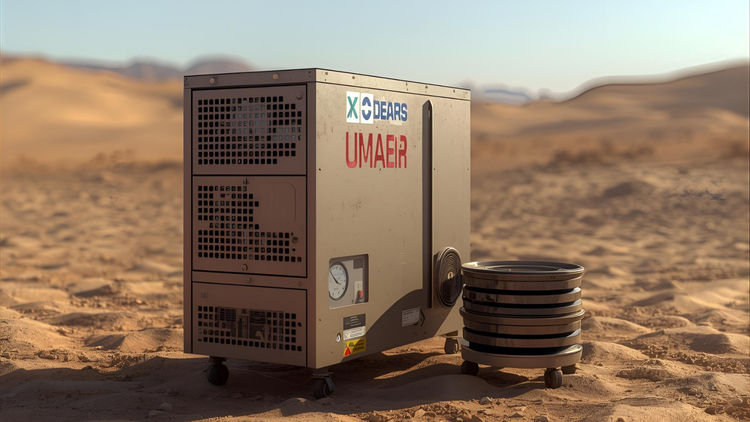

This case study examines how Think Robotics transformed initial concept sketches into a fully deployed military oxygen generation system that now serves soldiers in some of the world's most challenging operational environments.

The Challenge: Oxygen at Altitude

Military operations in high-altitude regions present unique medical challenges. Reduced atmospheric oxygen levels cause altitude sickness, impair cognitive function, and can lead to life-threatening conditions. While supplemental oxygen addresses these issues, transporting compressed oxygen cylinders to remote mountain outposts creates massive logistical burdens.

The Indian Army needed a solution that could generate oxygen on-site, eliminating supply chain dependencies while maintaining the reliability standards that military medical equipment demands. The system requirements were exacting: produce medical-grade oxygen with 93 percent or higher purity, operate in temperatures ranging from negative 20 to positive 50 degrees Celsius, withstand vibration and shock during transport, and function at altitudes up to 18,000 feet where the air pressure is roughly half that at sea level.

Traditional oxygen concentrator designs optimized for clinical environments wouldn't survive these conditions. The project required fundamental engineering to create a ruggedized equipment design capable of military deployment while meeting medical device standards.

Selecting the Core Technology: Pressure Swing Adsorption

After evaluating multiple oxygen generation technologies, Think Robotics selected pressure swing adsorption as the foundation for the military grade equipment development. PSA technology uses zeolite molecular sieves to selectively adsorb nitrogen from compressed air, producing an oxygen-enriched output stream.

PSA oxygen generator systems offer significant advantages for field deployment. Unlike cryogenic separation, PSA requires no consumable liquids. Unlike membrane separation, PSA achieves the high purity levels required for medical applications. The technology can start producing oxygen within minutes of activation and scales effectively from portable units to large installations.

The National Institutes of Health research confirms that PSA-generated oxygen meets medical gas purity standards when properly designed and maintained, making it suitable for both emergency medical treatment and acclimatization support.

However, adapting PSA technology for military field use required solving several engineering challenges. Zeolite performance degrades with moisture exposure, yet high-altitude environments feature extreme humidity variations. Compressor reliability becomes critical when maintenance facilities may be days away. Power efficiency matters significantly when operating from generators or solar installations with limited capacity.

Custom System Architecture and Design

Think Robotics developed a modular system architecture that balanced performance, reliability, and maintainability. The oxygen generation system design incorporated three primary subsystems: air intake and compression, PSA separation, and oxygen storage and delivery.

The air intake system featured multi-stage filtration to remove particulates, moisture, and contaminants before compression. Military operations generate dust, smoke, and other airborne materials that would quickly foul standard filtration. Custom filter housings allowed rapid field replacement without tools, while pressure differential sensors indicated when filter changes were needed.

Compression represented the most critical reliability challenge. Standard industrial compressors lack the ruggedization necessary for military deployment. Think Robotics selected an oil-free scroll compressor design and developed custom mounting systems that isolated the compressor from shock and vibration. Temperature management systems prevented overheating in high ambient temperatures while electric heating elements protected against freezing in extreme cold.

The PSA beds used dual-tower configuration where one tower produces oxygen while the other regenerates. Custom valve manifolds controlled the precise timing of pressure changes, optimized through extensive testing to maximize both oxygen purity and production efficiency. Oxygen purity measurement occurred continuously using electrochemical sensors calibrated to medical device standards, ensuring medical-grade output even as zeolite performance gradually changed over time.

Ruggedization and Environmental Protection

Transforming the core PSA system into a field deployable oxygen system required comprehensive environmental protection. Think Robotics designed a sealed enclosure that maintained internal temperature within operating ranges regardless of external conditions.

Thermal management combined passive and active approaches. High-density insulation minimized heat exchange with the environment. Internal heat generated by compression was channeled through heat exchangers that could either reject heat to the atmosphere or retain it for cold weather operation. Electric heating elements activated automatically when internal temperatures approached lower operating limits.

The enclosure withstood the rigors of military transport. Reinforced mounting points distributed shock loads across the frame structure. Sealed cable penetrations prevented moisture and dust ingress. External surfaces received corrosion-resistant coatings suitable for high-altitude UV exposure and temperature cycling.

Power systems accommodated multiple input sources. The primary design operated on 230V single-phase power, but alternate configurations accepted DC input from military vehicle electrical systems or solar installations. Power conditioning circuits protected sensitive electronics from voltage fluctuations common in field power distribution.

Testing and Validation Process

Before accepting any defense equipment manufacturing project for military deployment, extensive testing validates performance across operational conditions. Think Robotics developed comprehensive test protocols that exceeded standard medical device requirements.

Environmental testing subjected prototype units to temperature cycling between negative 30 and positive 60 degrees Celsius. Altitude chambers simulated operation at 20,000 feet. Vibration testing followed MIL-STD-810 protocols that replicate transport in military vehicles and helicopters. Each test phase identified design weaknesses that drove iterative improvements.

Field trials with Army medical units provided invaluable real-world validation. Operators unfamiliar with the system tested whether training materials were adequate and controls were intuitive. Medical personnel evaluated whether oxygen delivery met their clinical requirements. The U.S. Department of Defense emphasizes that operational testing in realistic conditions often reveals issues that laboratory testing misses, making field trials essential for military systems validation.

Manufacturing and Quality Assurance

Transitioning from prototype to production required establishing manufacturing processes that maintained the quality standards military applications demand. Think Robotics developed detailed assembly procedures, component inspection criteria, and testing protocols for production units.

Each system undergoes individual acceptance testing before delivery. This includes full-power operation for 72 continuous hours while monitoring oxygen purity, flow rate, and power consumption. Leak testing verifies all pressure vessels and connections meet safety standards. Calibration of sensors and alarms ensures accurate operation across the specified range.

Documentation for military deliveries includes complete parts lists, assembly drawings, maintenance manuals, and test records. Component selection emphasized long-term availability, with Think Robotics specifying components with broad industrial adoption rather than specialized parts that might become obsolete.

Deployment Results and Impact

The deployed portable oxygen concentrator system successfully addresses the operational requirements that initiated the project. Army medical units report reliable oxygen supply at high-altitude posts that previously depended on periodic resupply of compressed oxygen cylinders.

Soldiers experiencing altitude sickness receive immediate treatment without waiting for evacuation or oxygen delivery. Units conducting acclimatization before high-altitude operations have unlimited oxygen availability for controlled exposure protocols that reduce altitude-related medical issues.

The logistics impact proves equally significant. Eliminating regular oxygen cylinder deliveries to remote outposts reduces helicopter flight requirements and associated risks. The generated oxygen costs a fraction of bottled oxygen when accounting for production, transport, and handling expenses.

System reliability in field conditions has exceeded initial projections. Units report minimal maintenance requirements beyond scheduled filter changes and routine inspections. The modular design allows field replacement of key components without returning systems to depot facilities.

Think Robotics continues supporting the deployed systems through our defense contracting services, providing technical assistance, spare parts, and periodic upgrades as component technologies improve. Our experience with this project informs ongoing development of other ruggedized systems for military and industrial applications in extreme environments.

Engineering Lessons and Future Applications

Developing this custom oxygen generator provided insights applicable to broader industrial oxygen generation and field-deployable equipment design. The thermal management approaches developed for extreme temperature operation now inform other product designs. The ruggedization techniques apply to any equipment requiring military-grade reliability.

The modular architecture that facilitates field maintenance influences how Think Robotics approaches system design across projects. Equipment users shouldn't need specialized tools or extensive training to perform routine maintenance. Systems should degrade gracefully rather than failing catastrophically, with clear indicators of component health.

Interest from other military forces and civilian applications in remote areas suggests broader markets for field-deployable life support equipment. Mining operations at altitude, disaster response scenarios, and expedition medicine all present similar requirements for reliable oxygen generation in challenging environments.

The aerospace oxygen systems industry continues evolving toward lighter, more efficient designs. Advances in zeolite materials, compressor efficiency, and sensor technology create opportunities for next-generation systems with improved performance and reduced power consumption.

Conclusion

Transforming a concept into a deployed military oxygen generation system required more than technical engineering. Success demanded deep understanding of operational requirements, rigorous testing protocols, manufacturing discipline, and ongoing support commitment.

Think Robotics specializes in developing custom solutions for demanding applications where commercial off-the-shelf products fall short. Our embedded systems expertise and prototyping capabilities allow rapid iteration from initial concept through field-ready hardware.

Whether your project involves life support equipment, industrial automation, or specialized measurement systems, Think Robotics brings the engineering depth and project execution experience to deliver solutions that meet your operational requirements. The oxygen generation project demonstrates our ability to handle complex technical challenges while meeting the stringent quality and reliability standards that critical applications demand.