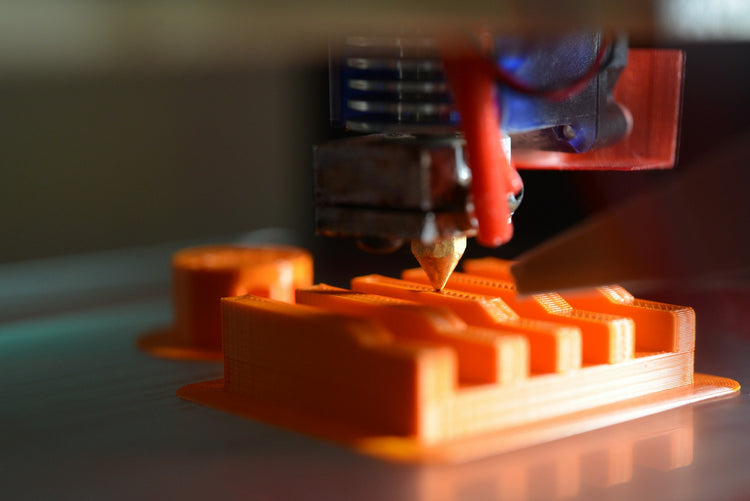

3D printing, also known as additive manufacturing, is transforming the manufacturing landscape and playing a crucial role in the emergence of Industry 4.0. In this blog post, we'll explore how 3D printing is revolutionizing embedded systems and contributing to the fourth industrial revolution.

- The Emergence of Industry 4.0 Industry 4.0 is the latest phase in the evolution of industrial production, characterized by the integration of digital technologies, automation, and data-driven decision-making. This revolution builds on the advancements of the previous three industrial revolutions - mechanization, mass production, and computerization. Industry 4.0 brings together the Internet of Things (IoT), artificial intelligence (AI), robotics, and advanced data analytics to create smart factories with increased efficiency, productivity, and flexibility.

- 3D Printing and Embedded Systems Embedded systems are an essential component of Industry 4.0, as they enable the integration of hardware and software for controlling various industrial processes. 3D printing is revolutionizing embedded systems by providing greater design freedom, faster prototyping, and cost-effective production of complex parts. Traditional manufacturing methods often impose limitations on design, but 3D printing allows for the creation of intricate geometries and lightweight structures that were previously unattainable. This design flexibility enables engineers to develop more efficient and compact embedded systems, reducing material waste and energy consumption. Rapid prototyping is another benefit of 3D printing, enabling engineers to quickly iterate and test their designs. This accelerated development process leads to faster time-to-market and reduced costs.

- Customization and On-Demand Production One of the most significant advantages of 3D printing is the ability to produce customized products and components on-demand. This is particularly valuable for embedded systems, where specific requirements may vary across different applications and industries. With 3D printing, manufacturers can easily modify designs to meet unique customer needs without the need for costly retooling. This level of customization enables the development of tailored embedded systems, enhancing performance and functionality for specific applications. On-demand production also reduces the need for large inventories, as parts can be printed when required. This minimizes storage costs and promotes a more sustainable and efficient supply chain.

- The Future of 3D Printing in Industry 4.0 As Industry 4.0 continues to evolve, 3D printing is expected to play an increasingly critical role in shaping the future of manufacturing. The integration of 3D printing with other Industry 4.0 technologies, such as AI, IoT, and robotics, will lead to even greater advancements in embedded systems. Digital twin technology, for example, uses virtual models to simulate and optimize physical systems. Combining 3D printing with digital twins can enable real-time feedback and adjustments during the design and production process, resulting in improved performance and reduced waste. Another promising development is the use of advanced materials in 3D printing, such as conductive materials and smart materials with embedded sensors. These materials can be used to create embedded systems with enhanced functionality, such as self-monitoring and self-healing capabilities.

In conclusion, 3D printing is a critical element in Industry 4.0, providing numerous benefits to embedded systems, including design flexibility, rapid prototyping, customization, and on-demand production. As the technology continues to advance and integrate with other Industry 4.0 technologies, we can expect to see even more innovative applications and improvements in the world of embedded systems and manufacturing as a whole.

Dear sir

I require the robot use in 3d printing