Building an Automatic Dispenser: A Comprehensive Guide

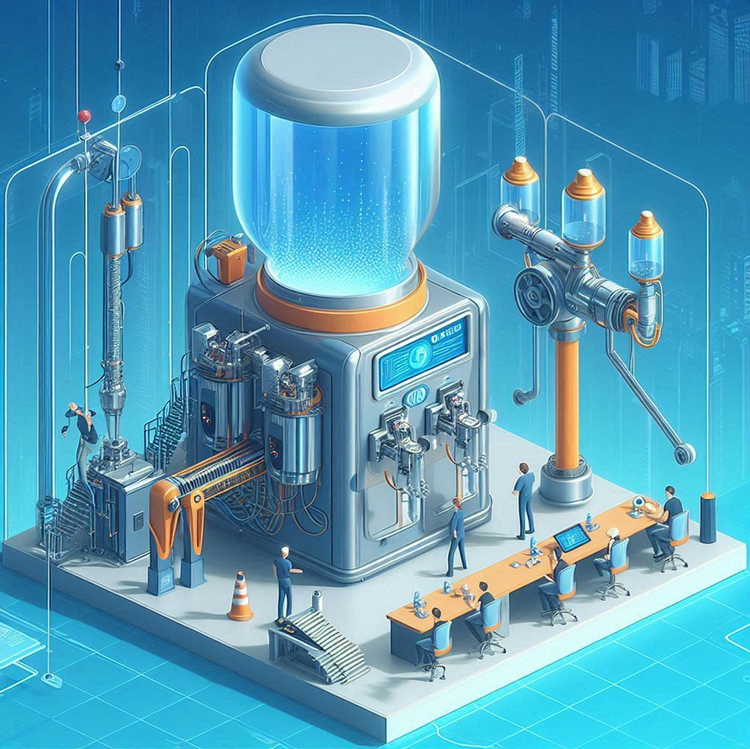

An automatic dispenser is a device that delivers a specific amount of a product, often liquid or solid, without human intervention. They are widely used in industries ranging from food and beverage to pharmaceuticals and automotive. In this article, we will delve into the process of creating an automatic dispenser, covering various design considerations, components, and programming techniques.

Types of Automatic Dispensers

Automatic dispensers can be categorized based on their dispensing mechanism, application, and level of automation. Here are some common types-

Pump Dispensers: These use pumps to dispense liquids or semi-liquids. They are commonly used in industries such as food and beverage, pharmaceuticals, and automotive.

Valve Dispensers: These use valves to control the flow of liquids or gases. They are commonly used in applications where precise dispensing is required, such as in the chemical and pharmaceutical industries.

Screw Feeders and Augers: These are used to dispense powders and granules. They are commonly used in the food, pharmaceutical, and chemical industries.

Food and Beverage Dispensers: These are used to dispense beverages, condiments, and other food products. Examples include soda dispensers, coffee dispensers, and ketchup dispensers.

Pharmaceutical Dispensers: These are used to dispense medications and other pharmaceutical products. Examples include pill dispensers and liquid medication dispensers.

Industrial Dispensers: These are used in various industrial applications, such as dispensing lubricants, adhesives, and coatings.

Design Considerations

Before embarking on the construction of an automatic dispenser, it is essential to carefully consider the following factors-

-

Product Type: The nature of the product will dictate the appropriate dispensing mechanism. For example, liquids might require a pump or valve, while powders or granules might necessitate a screw feeder or auger.

-

Dispensing Volume: The desired quantity of product to be dispensed will influence the size and precision of the dispensing mechanism.

-

Container Type: The shape and size of the containers that will be used will determine the design of the dispenser's interface.

- Level of Automation: The desired level of automation will impact the complexity of the control system. Some dispensers might be fully automated, while others might require manual intervention for specific tasks.

Components

A typical automatic dispenser consists of the following components-

- Dispensing Mechanism: This is the core component responsible for delivering the product. It can vary widely depending on the product type, but common options include:

-Pumps: Centrifugal, peristaltic, or piston pumps are suitable for liquids.

-Valves: Solenoid or pneumatic valves can control the flow of liquids or gases.

-Screw Feeders: These are used for powders and granules.

-Augers: Similar to screw feeders, but with a helical shaft.

-

Container Handling System: This component is responsible for positioning and holding containers during the dispensing process. It can be as simple as a conveyor belt or as complex as a robotic arm.

- Sensor System: Sensors are used to monitor the dispensing process and provide feedback to the control system. Common sensors include:

-Level Sensors: These measure the level of product in the dispenser.

-Flow Sensors: These measure the rate of flow of the product.

-Pressure Sensors: These measure the pressure in the dispensing system.

- Control System: The control system is the brain of the dispenser, responsible for coordinating the actions of the various components. It can be a simple microcontroller or a complex PLC.

Programming

The programming of an automatic dispenser involves creating a set of instructions that define the dispenser's behavior. This typically involves-

-

Input/Output (I/O) Handling: The program must handle inputs from sensors and outputs to actuators.

-

Control Logic: The program must implement the control logic that determines the actions of the dispenser based on sensor readings and user input.

-

Error Handling: The program must be able to detect and handle errors that may occur during the dispensing process.

- User Interface: If the dispenser has a user interface, the program must handle interactions with the user.

Case Study: A Liquid Soap Dispenser

To illustrate the concepts discussed above, let's consider a simple liquid soap dispenser.

Design Considerations:

- Product Type: Liquid

- Dispensing Volume: 1 mL

- Container Type: Plastic bottle

- Level of Automation: Fully automated

Components:

- Dispensing Mechanism: Peristaltic pump

- Container Handling System: Simple gravity-fed system

- Sensor System: Level sensor in the soap reservoir

- Control System: Microcontroller

Programming:

- Initialize Components: Power on the pump and level sensor.

- Check Soap Level: Read the level sensor to determine if there is enough soap.

- Dispense Soap: If there is enough soap, activate the pump for a predetermined time to dispense 1 mL.

- Check for Dispensing Errors: Monitor the pump's current to detect any errors.

- Repeat: If the dispensing was successful, return to step 2.

Conclusion

Creating an automatic dispenser involves a careful consideration of design factors, selection of appropriate components, and development of effective programming. By following the guidelines outlined in this article, you can successfully build a reliable and efficient dispenser for a variety of applications.