Servo motors are a critical component in robotics, offering the precision and control needed to drive robotic arms, wheels, and other actuators. These motors are designed to provide exact position control, making them essential for many robotic applications, from industrial automation to consumer robots. Whether you're building a robotic arm, drone, or mobile robot, servo motors are integral to achieving smooth and efficient operation. This blog will explore the role of servo motors in robotics, their benefits, and how companies like ThinkRobotics are innovating in this space.

What Are Servo Motors?

A servo motor is a type of electric motor that is capable of rotating to a precise position and maintaining that position. This is achieved using feedback loops that ensure the motor turns to the correct angle and stays there, even when under load. Unlike regular motors that run continuously at a constant speed, servo motors only rotate a specific angle, usually controlled by a microcontroller or a control signal.

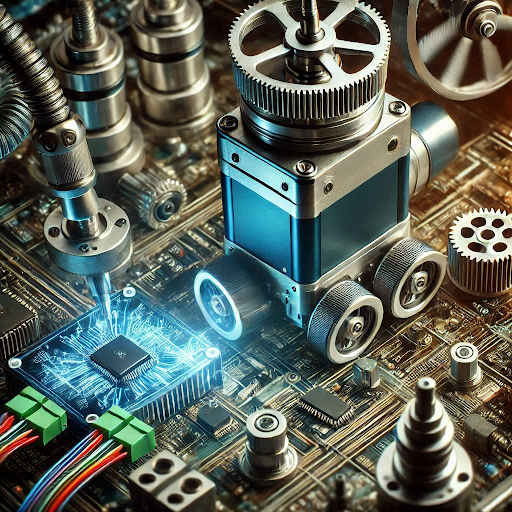

The basic mechanism behind a servo motor includes a motor, a geartrain, a feedback sensor, and a controller. The motor generates rotational motion, while the geartrain reduces the motor speed and increases torque. The feedback sensor, typically an encoder or potentiometer, continuously monitors the position and sends this information to the controller, which adjusts the motor's motion accordingly.

Servo motors are typically classified based on their size, torque capacity, and speed, and they can be AC (alternating current) or DC (direct current) powered. In robotics, DC servo motors are often used due to their smaller size, efficiency, and ease of control.

Why Are Servo Motors Important for Robotics?

Servo motors offer several advantages that make them ideal for robotic applications:

-

Precision and Accuracy: Robotics demands high precision, and servo motors excel in this regard. They can rotate to specific positions within a fraction of a degree, making them ideal for tasks that require fine-tuned movements such as robotic arms, grippers, or legs in humanoid robots.

-

High Torque: Servo motors provide high torque relative to their size, which is crucial for tasks requiring powerful movements, such as lifting objects, driving wheels, or manipulating tools.

-

Feedback Control: The feedback mechanism allows servo motors to adjust their performance in real-time, ensuring that the robot's movements are as accurate and reliable as possible.

-

Energy Efficiency: Servo motors only use power when moving, which makes them more energy-efficient compared to traditional motors that run continuously. This is especially important for battery-powered robots, such as drones or autonomous vehicles.

-

Compact Size: Servo motors are available in compact sizes, making them easy to integrate into small and lightweight robotic systems. This is particularly advantageous when designing mobile robots or wearable robotics.

Applications of Servo Motors in Robotics

Servo motors are used in a wide range of robotic applications:

-

Robotic Arms: Servo motors drive the joints of robotic arms, enabling them to perform precise movements for tasks like assembly, welding, or packaging. Their high accuracy and reliability are essential in industrial automation.

-

Mobile Robots: In mobile robots, servo motors control the wheels or tracks, providing precise movement and steering. This allows robots to navigate their environments with agility and accuracy.

-

Humanoid Robots: Servo motors are used in humanoid robots to drive the joints of the arms, legs, and head. These motors mimic human-like movements and are integral to making robots that can walk, run, and perform human-like actions.

-

Drone Robotics: Servo motors are also found in drones, where they control the rotation of the camera, gimbals, or flight stabilizers, ensuring smooth, controlled movements.

-

Automation Systems: In industrial settings, servo motors are commonly used in conveyor belts, sorting machines, and other automated systems, where precision, speed, and repeatability are critical.

ThinkRobotics: Innovating with Servo Motors

When it comes to cutting-edge robotics solutions, ThinkRobotics stands out as a key player in the industry. Specializing in automation systems, ThinkRobotics combines servo motors with advanced control systems to create highly efficient and precise robots that meet the needs of various industries.

ThinkRobotic is known for its expertise in developing customized robotic solutions that integrate servo motors for enhanced performance. Whether it's improving the precision of robotic arms used in manufacturing or optimizing the motion control of mobile robots, ThinkRobotics utilizes the latest in servo motor technology to ensure superior results. By offering advanced robotic systems powered by servo motors, ThinkRobotics is helping businesses across industries boost productivity, enhance accuracy, and improve operational efficiency.

Their servo motor-driven solutions are particularly advantageous in sectors such as logistics, automotive, and healthcare, where precision and reliability are paramount. ThinkRobotics is also committed to advancing the field by constantly refining their systems, ensuring that their robots can handle increasingly complex tasks with minimal human intervention.

Choosing the Right Servo Motor for Your Robotics Project

When selecting a servo motor for a robotics project, there are several factors to consider. These include the required torque, speed, and precision. It’s also important to choose the right control system to ensure the servo motor performs optimally.

-

Torque Requirements: Determine how much force is needed to move the robot's parts. Servo motors come in different torque ratings, so selecting the right one ensures your robot can perform the intended tasks.

-

Size and Weight: In applications like drones or small robots, size and weight are critical. Choose a servo motor that is compact but still capable of providing sufficient torque.

-

Control System Compatibility: Ensure that the servo motor is compatible with the robot's control system. Many servo motors have specific control requirements, such as pulse-width modulation (PWM) signals.

-

Speed and Precision: Depending on the application, you may need a motor with high speed or one that prioritizes precision. Choose a motor that aligns with your project’s needs.

Conclusion

Servo motors play an indispensable role in robotics, offering the precision, torque, and control necessary for a wide range of applications. Whether used in robotic arms, drones, or autonomous vehicles, servo motors are integral to the success of robotics systems. As companies like ThinkRobotics continue to innovate with servo motor technology, we can expect even greater advancements in robotic performance and efficiency. If you’re working on a robotics project, understanding the capabilities and benefits of servo motors is key to building a reliable and high-performing system.

For businesses and engineers looking to integrate advanced robotics into their operations, ThinkRobotics provides cutting-edge solutions powered by servo motors, delivering automation with precision and efficiency.