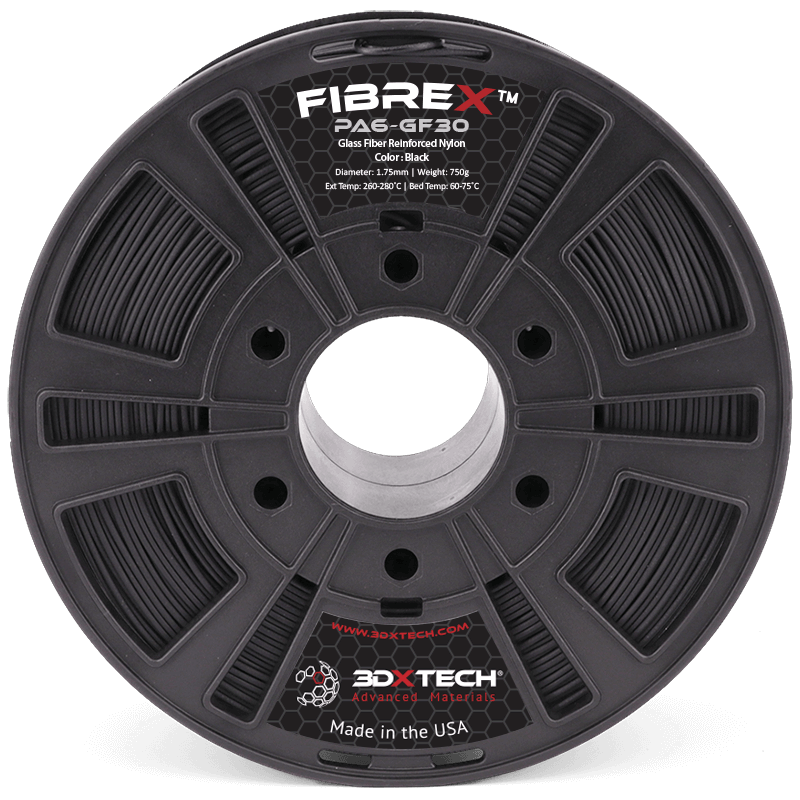

FibreX Nylon 6+GF30

Our Nylon+GF30 glass fiber reinforced Nylon 6 Copolymer (PA6) is nothing less than an industrial-grade beast! Formulated to be exceptionally stiff and strong, all without being brittle. Polyamides (PA) are the work horse of the plastics industry the world over thanks to their excellent mechanical, chemical, and thermal resistance. The addition of heavy glass fiber reinforcement takes it to the next level.

Benefits of Nylon+GF30 Include:

Printable on practically any 3D printer with a heated bed

Ideal for structural engineering-grade applications

Exceptionally stiff and strong, without being brittle

Excellent chemical resistance makes it suitable for automotive and industrial applications

Resists fuels, lubricants, heat, and mechanical loading

High thermal properties keep it strong up to 170°C in use, depending on printing and mechanical loads applied

Glass fiber reinforcement improves dimensional stability, reduces shrinkage, lift, and warp

Very strong layer bonding

This product contains 750 grams and 2kgs of filament.

2.85mm and 2KG Available on order only. (Lead time: <7 days)

Specifications

1.75mm and 2.85mm +/- 0.05mm in diameter

Print Recommendations

Extruder: 260-280°C

Bed Temp: 60-75°C

Nozzle: We currently recommend a hardened steel nozzle with a minimum diameter of 0.4mm

Other: Ideal layer height is 60% of nozzle diameter. We do not recommend printing layers smaller than 0.25mm with glass fiber reinforced filaments

Bed Prep: Magigoo Bed Prep or 3DXTECH Polyimide Tape gives us the best results

Heated Chamber: Not required, but a 30-80°C chamber does improve layer bonding and finished part mechanical properties

Supports: AquaTek™ water-soluble X1 USM Universal Support Material works ideal for complex parts.

Drying Instructions: 90°C for 4 hours.

New Digital Catalog

Packed with your favorite products, detailed information, and essential technical data. Whether your brand new to 3-D printing or need to find a specific filament that best fits your project, our catalog has everything you need in one easy-to-navigate place!

Product Performance Comparison

Explore key attributes like tensile strength, flexural strength, glass transition, and fire testing performance. Whether you're prototyping, creating functional parts, or printing detailed models, these property graphs will help you find the perfect filament for your project.

Glass Fiber Filament

What Is It?

Fibers made of glass reinforced into the polymer during manufacturing and aligned along the axis of filament. This, along with their physical makeup, give this material enormous strength and mechanical properties.

What Does It Do?

Glass fiber reinforcement gives material a lot of desirable properties:

High strength, High stiffness, High chemical resistance, Low thermal expansion

How Does It Work?

Reinforcing plastic with glass fibers produces a 3D printing filament that exhibits the best properties of both fiberglass and the plastic of choice.

What Is It Good For?

Ideal for any applications which require strength and rigidity. For these reasons, glass fiber reinforced filament is very popular in the automotive, mechanical, civil engineering, and research industries.

Abrasive Material

This material is particularly abrasive among 3D printing filaments. Users may find standard brass nozzles are chewed through very quickly compared to standard wear and tear. When worn through, the nozzle diameter will widen inconsistently, and the printer will experience extrusion issues. Because of this, it's strongly recommended this material be printed through a hardened steel nozzle rather than a softer metal. Hardened steel nozzles can often be inexpensive and easily installed depending on your printer manufacturer's instructions.

Resources

Want to buy in bulk?

Custom Requirements?

Discussion Forum

Feel free to ask questions, share tips or report issues.