Hiwonder 6 Channel Digital Servo Tester with Over-Current Protection

Specifications - 76mm*53mm(2.99in*2.09in); Weight: 37g (1.31oz)

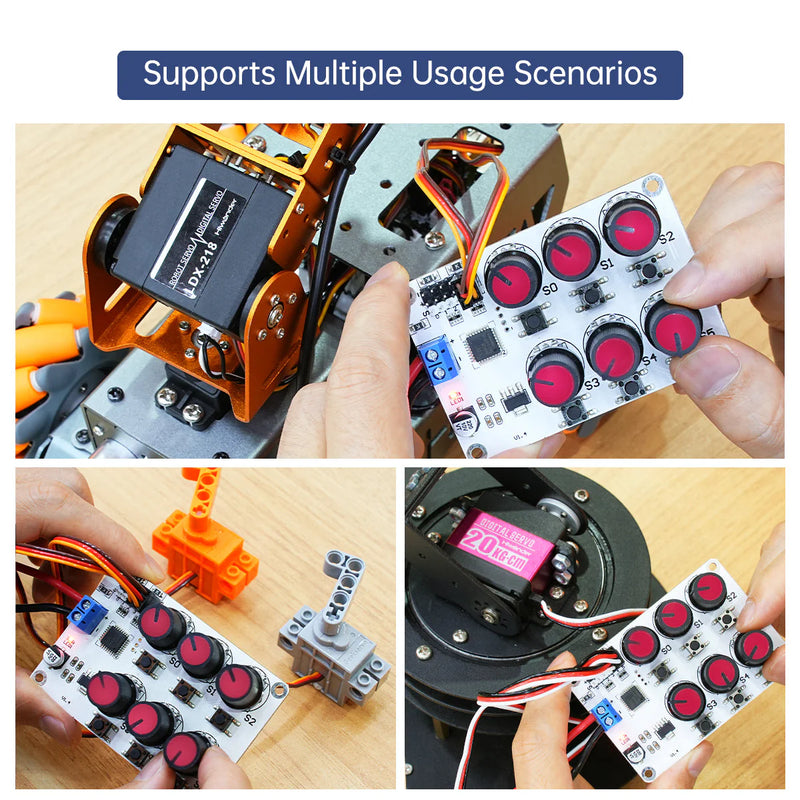

Versatile Applications - It can be applied in grippers, AI robots, robot arms and more.

Controller Accuracy - Its accuracy can reach up to 0.09° (with a 1us PWM limit for minimal changes)

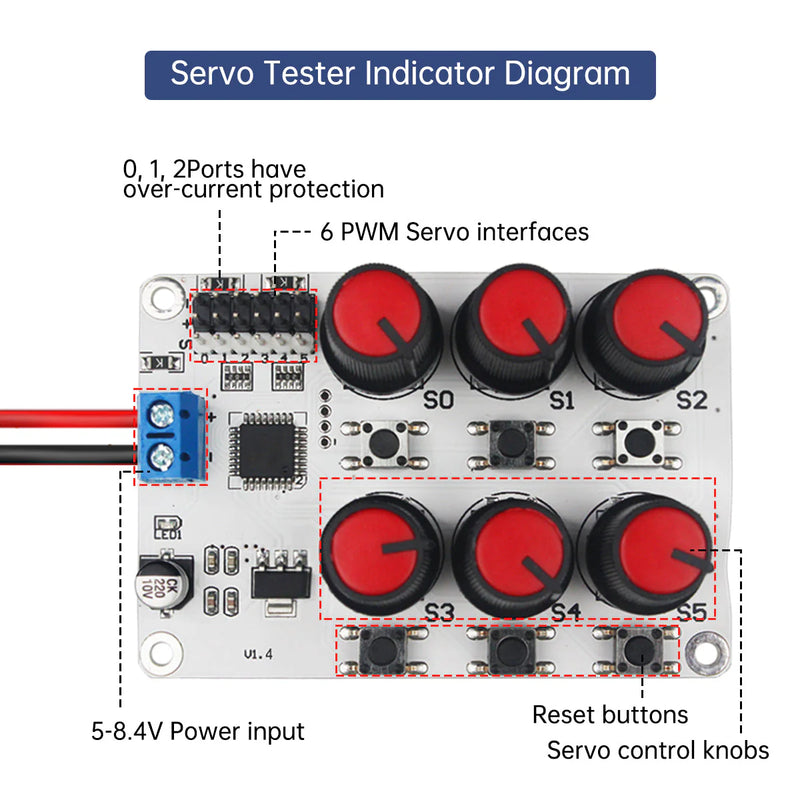

Overcurrent protection - The controller offers 3-channel overcurrent protection to prevent damage to the servo.

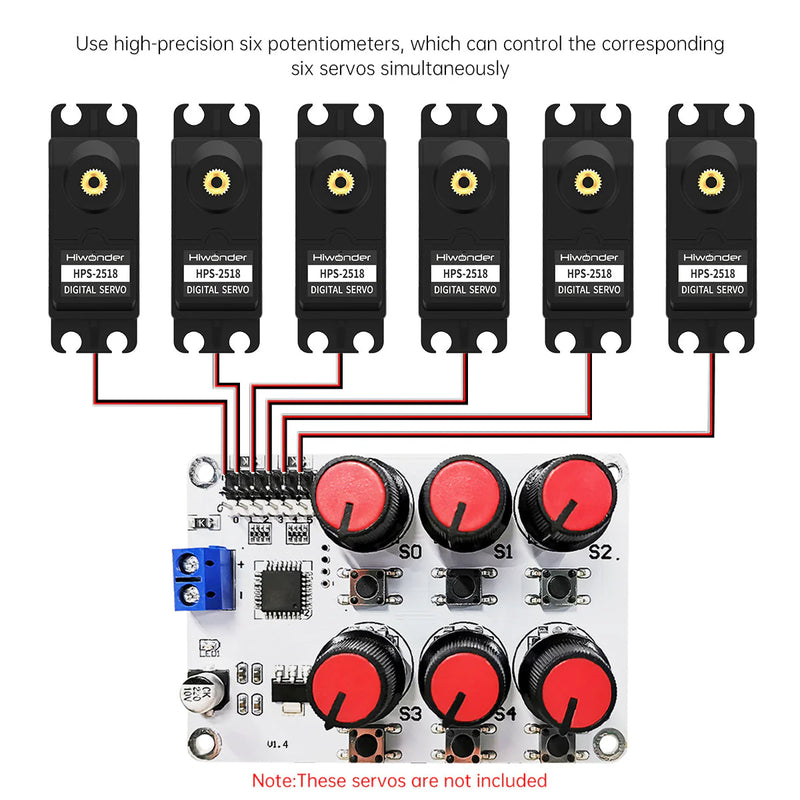

Support PWM Servo - It supports a wide variety of PWM servos, allowing manual angle adjustments without the need for coding.

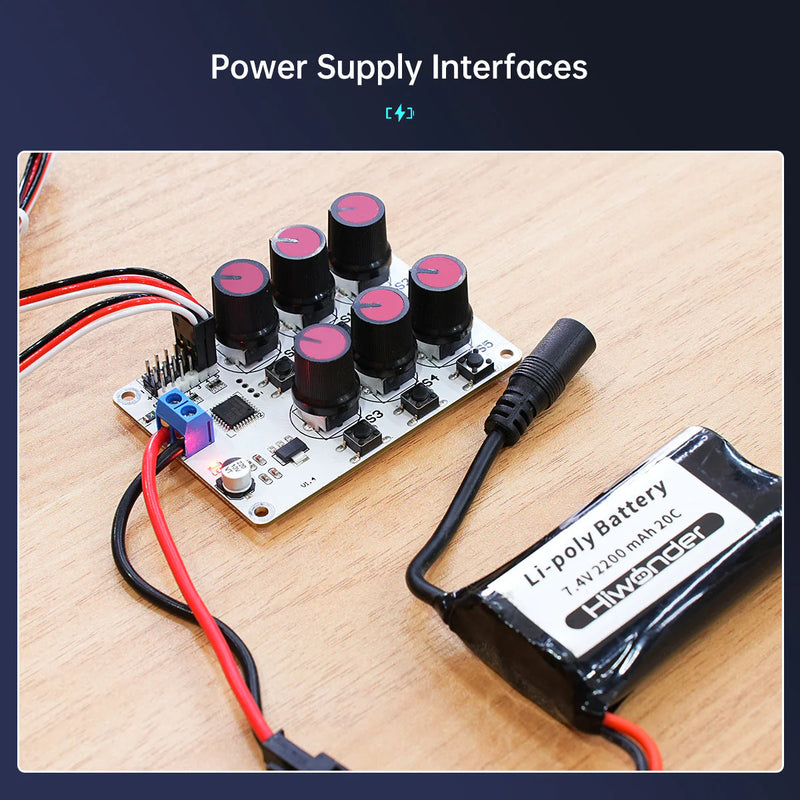

Power Supply - This controller can be powered by either a Lipo battery or a power adapter, operating within a voltage range of 5-8.4V.

Manual Adjustment - The controller has 6-channel PWM digital servo port, adopts high-accuracy potentiometer for precise servo control and provides servo reset function.

Two Power Supply Interfaces

Product Parameters

> High-precision potentiometer, which can control the servo in real-time.

> Onboard 3-way overcurrent protection interface (0.1.2 interface), which can prevent the steering gear from being burned out by excessive current.

> High-resolution PWM signal, on-board 8-bit MCU, can make the control accuracy higher.

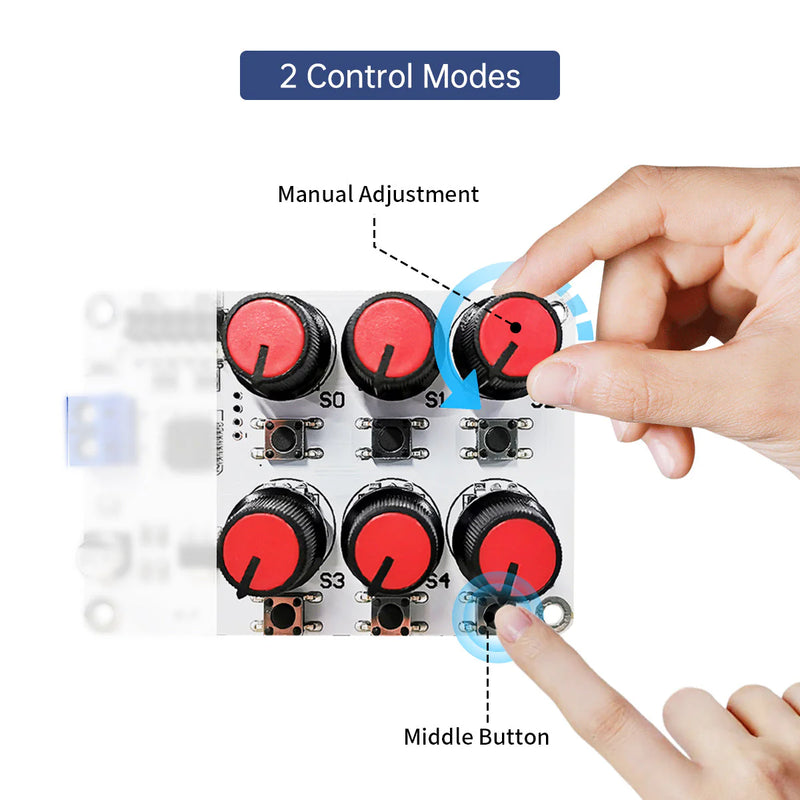

> Support manual steering gear controller / steering gear reset to center, switch by function button

> Accuracy of steering gear controller: 0.09° (refers to the minimum change value of PWM 1us)

> Compatible with two power supply link methods of lithium battery/power adapter. (5-8.4V)

> Onboard 6-way PWM digital servo interface, which can be controlled by high-precision potentiometer.

> The size of the 6-way knob is 76mm*53mm, and the weight is 37g.

How to Use:

> Supply power to the controller, the voltage can be 5~8.4V, the specific voltage is subject to the actual use of the servo's rated voltage.

> The servo is plugged into the 3Pin servo port, + is the positive pole, -is the negative pole, and S is the signal terminal.

> The power-on default potentiometer control mode, the servo rotates synchronously when the knob is turned.

> The button below the knob can switch the mode, press respectively to

"Manual Mode": Knob control.

"Neutral Mode": Return to the center position.

Information of Controller

"+" Positive Pole

"-" Negative Pole

"S" Signal Terminal

Manual Mode: Knob Control.

Neutral Mode: Return to Center Position.

Voltage Real-time Monitoring Through the voltage display module, the voltage of the power supply equipment can be monitored in real time to prevent the voltage from being too low to continue to control and test the steering gear. |

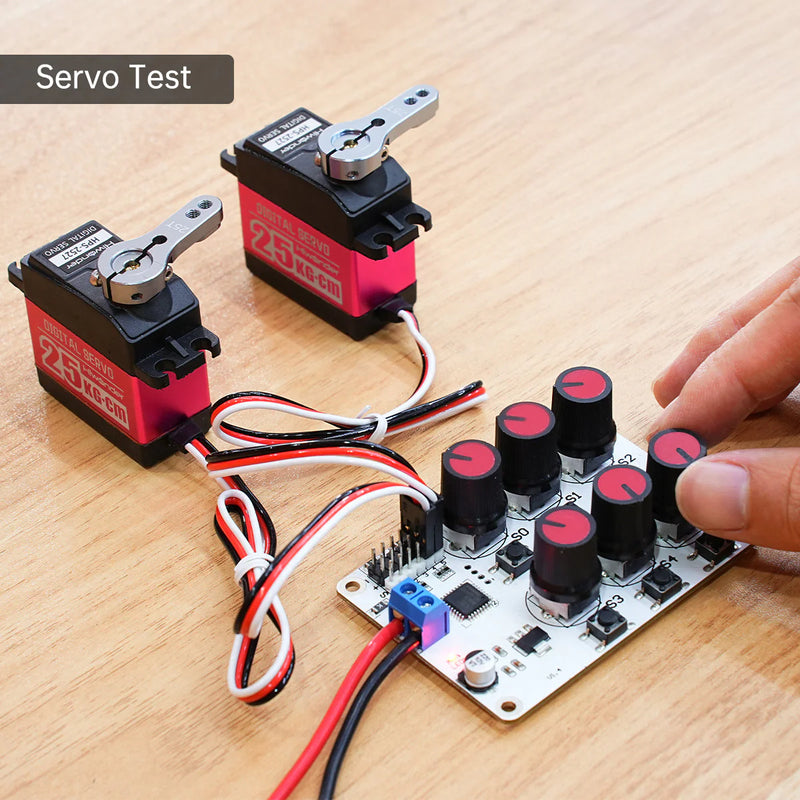

Manually Control the Servo Through the high-precision potentiometer, the angle synchronous rotation of the 2 steering gears can be controlled in real time. |

Servo Return to Center Through the reset button, the angle of the 2-way servo can be reset to 90°. |

Robotic Arm Debugging |

Claw Debugging |

Servo Gimbal Debugging |

Specifications

| Item | Servo Tester 1 Channels | Servo Tester 6 Channels | 20-60KG/180°-270° PWM Servo | 35KG/180°-270° Coreless Servo |

|---|---|---|---|---|

| Size | 2*1.4inch / 50*35mm | 3*2.1 inch / 76*53 mm | 1.57*0.8*1.59inch / 40*20*40.5mm | 1.57x0.79x1.5 inch / 40*20*38mm |

| Weight | 0.03 lb / 13.5g | 0.1 lb / 37g | 0.15LB / 66G | 0.13LB / 60G |

| Supply Voltage Range | 5-8.4V | 5-8.4V | 6-7.4v | 5-7.4v |

| Servo Controller Accuracy | 0.09° | 0.09° | 0.3° | 0.3° |

Want to buy in bulk?

Custom Requirements?

Discussion Forum

Feel free to ask questions, share tips or report issues.