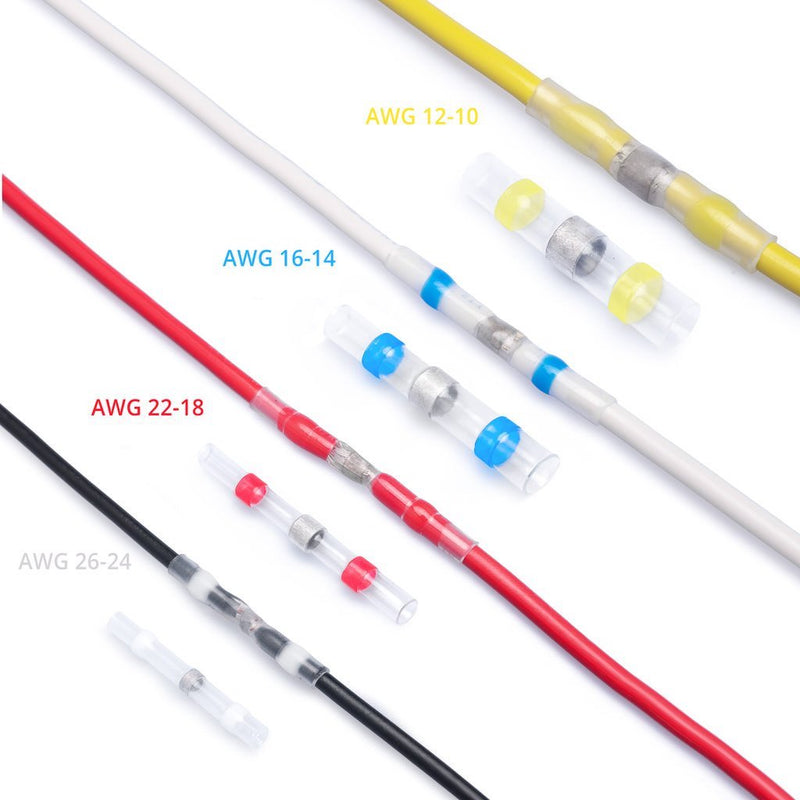

- Solderless and crimpless, all you need is just a heat gun to finish the joint, much faster and easier than the old way.

- Fit for Confined and Narrow Spaces - can be bent after connection and no need to crimp or solder in the confined area, just control the temperature via a heat gun.

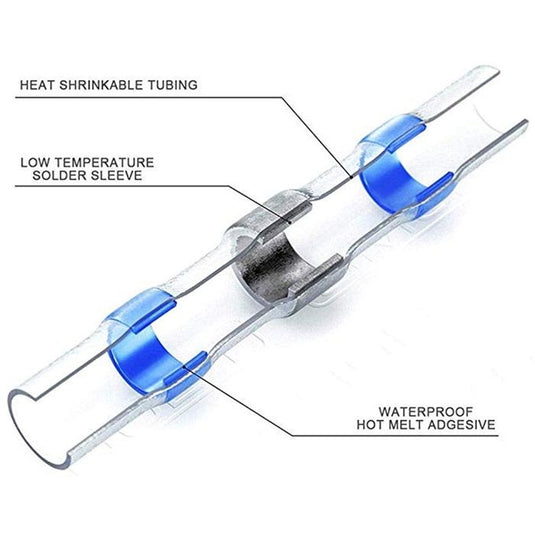

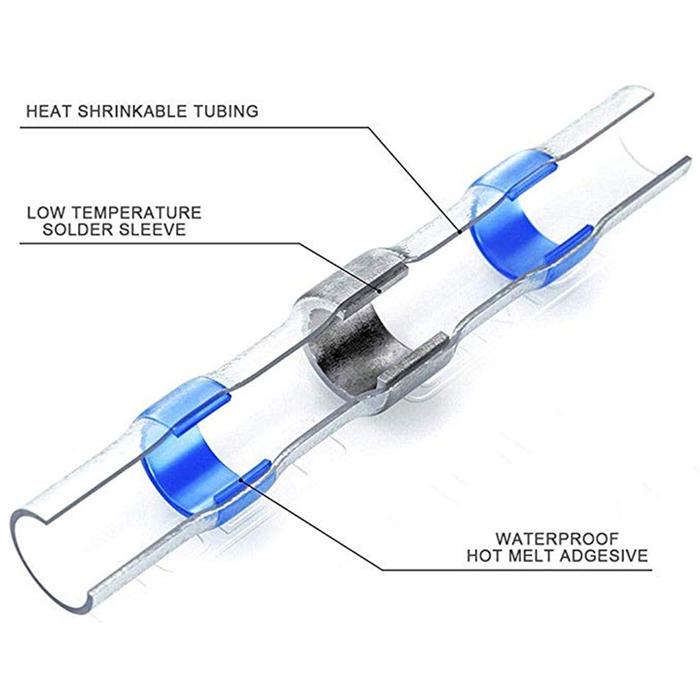

- Better Waterproof and Seal Performance - there is two hot melt waterproof adhesive rings in each butt connector, which help it hold up better to moisture.

- High Temperature Resistance in A Short Time: use exclusive material in the butt connectors to avoid shrink tubing melting before solder ring.

- Shrinkage ratio is 3:1

- Temperature that start to shrink: 80℃

- Temperature that solder ring start to melt: 111˚C

- Temperature that solder ring melt completely:138˚C

NOTE: Temperature of surface of the connector is what is mentioned above, rather than the temperature that the hot air gun should set.

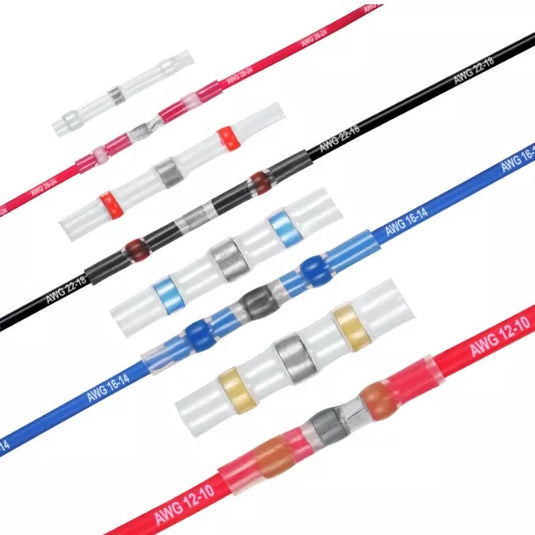

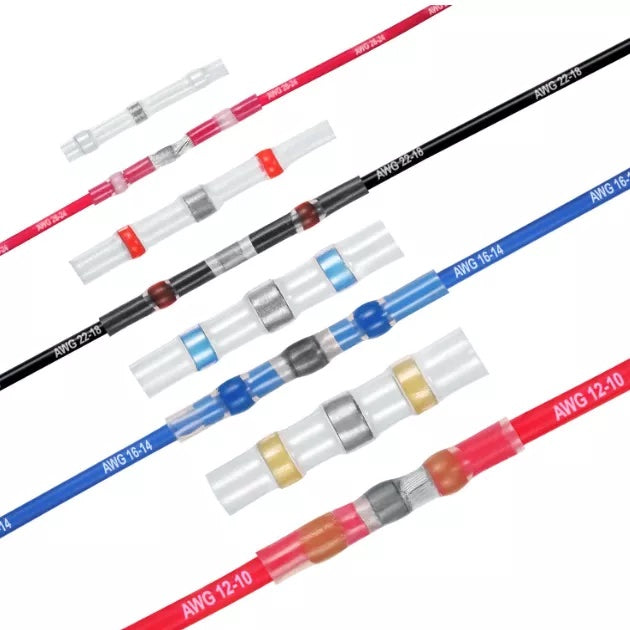

MIX Pack contains 5 pcs of each type of connector.

Want to buy in bulk?

Custom Requirements?

Discussion Forum

Welcome to the discussion thread for Waterproof Electrical Solder Seal Heat Shrink Connectors

Feel free to ask questions, share tips or report issues.

Feel free to ask questions, share tips or report issues.