Understanding the Crankshaft Position Sensor: How It Works, Common Issues, and Replacement Tips

The crankshaft position sensor (CPS) is one of the unsung heroes in modern engines. Without it, your engine wouldn't know when to fire, how to idle, or even how to start in the first place. In this blog, we’ll explore what a crankshaft position sensor does, how it works, and why it’s so crucial for your vehicle’s performance and efficiency. We’ll also cover the common symptoms of a failing sensor and what you can do to fix or replace it.

What is a Crankshaft Position Sensor?

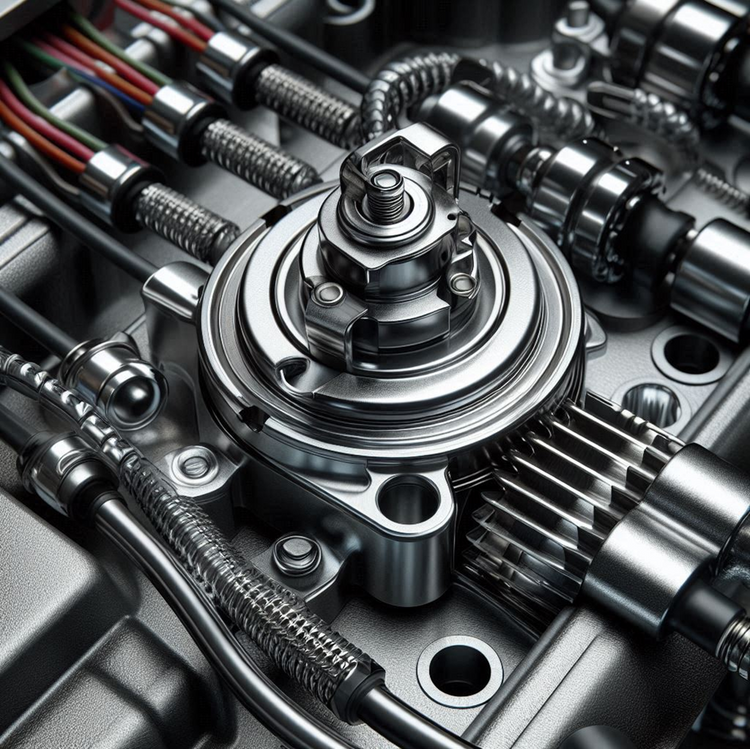

The crankshaft position sensor is an electronic device responsible for monitoring the rotational speed and position of the crankshaft. The crankshaft is a central part of the engine that converts linear motion from the pistons into rotational motion, which drives the wheels. The position sensor ensures that the fuel injection and ignition timing are in perfect sync with the movement of the pistons, optimizing performance and fuel efficiency.

Located near the crankshaft, typically at the front or back of the engine block, the CPS sends data to the engine control unit (ECU), which then uses this information to determine the correct timing for fuel injection and spark ignition. This synchronization is crucial because it prevents the engine from misfiring, stalling, or operating inefficiently.

Suggested Read: Crankshaft Position Sensor: How it Keeps Your Engine Running SmoothlyHow Does the Crankshaft Position Sensor Work?

The crankshaft position sensor relies on either a magnetic or optical system to detect the crankshaft's position. There are three main types of CPS-

-

Magnetic Sensors: These use a magnet and a coil. As the crankshaft spins, it interrupts the magnetic field, producing an alternating current (AC) signal. This AC signal is sent to the ECU, which decodes it into useful timing data.

-

Hall Effect Sensors: A Hall Effect sensor uses a small magnet attached to a sensor. As the crankshaft rotates, it moves past the magnet, which causes changes in the sensor's electrical field. This information is then converted to a digital signal, which is sent to the ECU.

- Optical Sensors: Optical sensors use a light emitter and receiver, often a laser or LED. As the crankshaft spins, it interrupts the light path, sending data on the crankshaft’s position to the ECU.

Each sensor type has its own benefits, but they all serve the same purpose: providing highly accurate data to ensure the ECU can precisely control the engine’s timing.

Importance of the Crankshaft Position Sensor

The CPS is fundamental to an engine's operation for several reasons-

-

The sensor ensures that the engine’s spark plugs fire at the right time, which is critical for efficient combustion. This is particularly important in high-performance engines, where even minor timing discrepancies can cause noticeable performance drops.

-

By optimizing timing, the CPS helps the ECU control fuel injection, resulting in better fuel economy. A faulty sensor can lead to poor fuel efficiency and increased emissions.

-

Without a properly functioning CPS, the engine can misfire, which can lead to overheating and potential damage to internal components.

-

The CPS plays a role in maintaining a steady idle, which means the car won’t shudder or stall unexpectedly when it’s not in motion.

- Because the CPS keeps the fuel injection and timing precise, it minimizes unburnt fuel entering the exhaust, reducing harmful emissions.

Symptoms of a Faulty Crankshaft Position Sensor

Given its critical role, a failing crankshaft position sensor can create noticeable issues. Here are the most common symptoms-

-

One of the first signs of a failing CPS is the activation of the check engine light. The ECU often logs a code when it detects a problem with the sensor.

-

A faulty CPS can result in delayed or failed engine starts because the ECU lacks the necessary data to initiate combustion correctly.

-

If the CPS fails while driving, it may cause the engine to stall or cut out suddenly. This can be especially dangerous if you’re driving at high speeds.

-

Incorrect timing caused by a malfunctioning CPS can lead to misfires or rough idling, making for a less smooth driving experience.

- Without the CPS accurately controlling timing, fuel consumption can increase, causing your car to use more fuel than usual.

Causes of Crankshaft Position Sensor Failure

The CPS is subject to wear and tear over time, especially since it’s located in a part of the engine that gets exposed to high temperatures and vibrations. Here are some common reasons why CPS might fail-

-

Heat Damage: High engine temperatures can degrade the sensor’s components over time, leading to intermittent or total failure.

-

Vibrations and Mechanical Stress: Continuous vibrations can loosen the sensor or wear down its components, leading to signal loss.

-

Electrical Issues: Damaged wires, connectors, or corroded terminals can result in poor or no signal transmission from the sensor to the ECU.

-

Debris and Oil Contamination: The sensor’s position near the crankshaft exposes it to potential contamination from oil leaks or debris. This can impair its performance or lead to a complete malfunction.

- Wear and Tear: Like all engine components, the CPS has a limited lifespan and may simply wear out over time.

Diagnosing a Faulty Crankshaft Position Sensor

If you experience any symptoms of a faulty CPS, it’s essential to diagnose the issue properly. A mechanic can use a scan tool to read the error codes stored in the ECU, often revealing if the CPS is the root cause. In some cases, mechanics may perform a physical inspection or use a multimeter to check for proper voltage in the sensor’s circuit.

Replacing a Crankshaft Position Sensor

If your CPS is faulty, replacement is usually the best solution. Here’s a brief overview of the process-

-

Locate the Sensor: The CPS is usually located near the crankshaft, typically at the front of the engine block or near the transmission.

-

Disconnect the Battery: Always disconnect the battery before working on any engine component to avoid potential electrical issues.

-

Remove the Sensor: Depending on the sensor’s position, you may need to remove other engine components to access it. Loosen the mounting bolts and carefully remove the sensor.

-

Install the New Sensor: Place the new sensor in the same position and secure it with the mounting bolts. Ensure that all connections are secure to avoid future issues.

- Reconnect the Battery and Test: Once the new sensor is installed, reconnect the battery and start the engine. A successful repair will eliminate any CPS-related issues, such as stalling or rough idling.

Conclusion

The crankshaft position sensor is a vital component in modern engines, allowing for precise timing that directly impacts performance, fuel efficiency, and emission control. Recognizing the symptoms of a failing sensor early can prevent costly repairs down the line and help maintain a smoother, safer driving experience. If you suspect your CPS is faulty, consult with a qualified mechanic for a diagnosis and replacement. While it may seem like a small part, the crankshaft position sensor plays an essential role in keeping your vehicle running at its best.

My vehicle was stolen 2009chevy express 3500 6.0. After the initial relearn procedure to get the vehicle started, it ran fine. Having to switch battery to the correct one, I had to redo a partial relearn. I didn’t expect the engine to crank on the first key turn but it actually started for a brief two seconds as b

eing caught off guard I quickly turned the key off and back on. Could this rapid succession have shorted out or surged the CPS as the motor cranks strong with intermittent grinding noise. Acts like no spark-jumped timing. Motor will not start when all was fine two hour,prior. Could I have damaged crank position sensor this way?