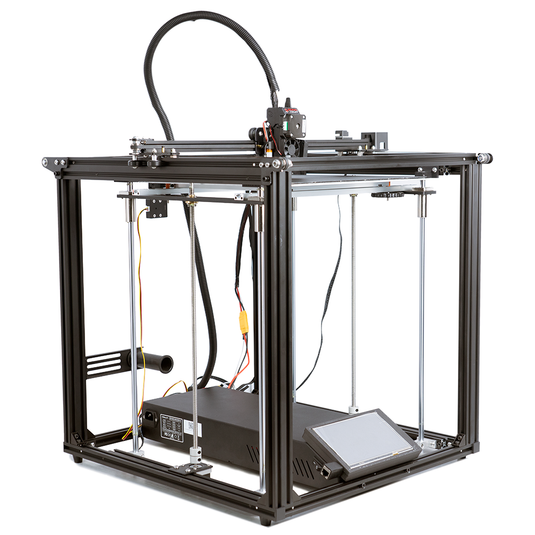

The ThinkRobotics Ender 5+ (Ender 5 Plus) with BondTech extruder upgrade and Duet3 6HC MainBoard is our latest offering in the world of upgraded 3D printers that enable 3D printing 24/7 365 days a year with exotic materials like Carbon Fiber Nylon.

These are the 3D printers that we use at our Printing Farm, producing carbon fiber plastic products for our industrial customers, and fulfilling a variety of industrial 3d printing projects.

Production lead time is 2-3 weeks once the order is placed. We provide remote training sessions and support.

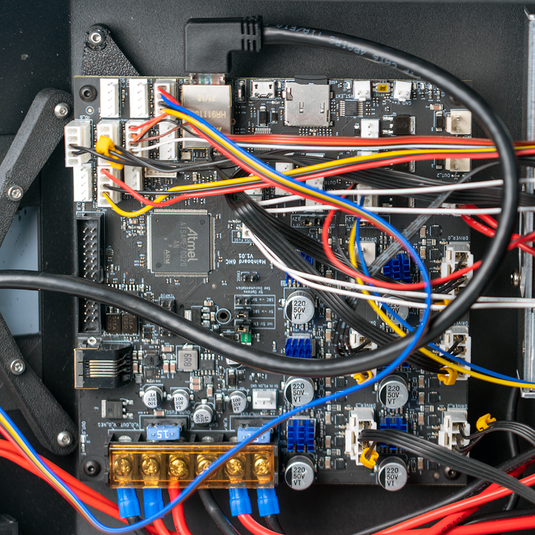

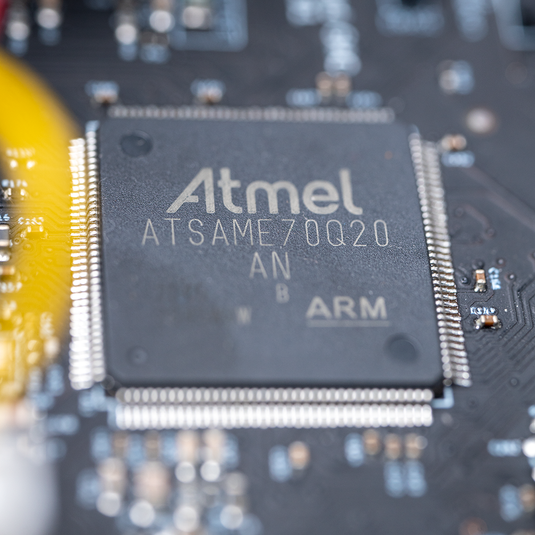

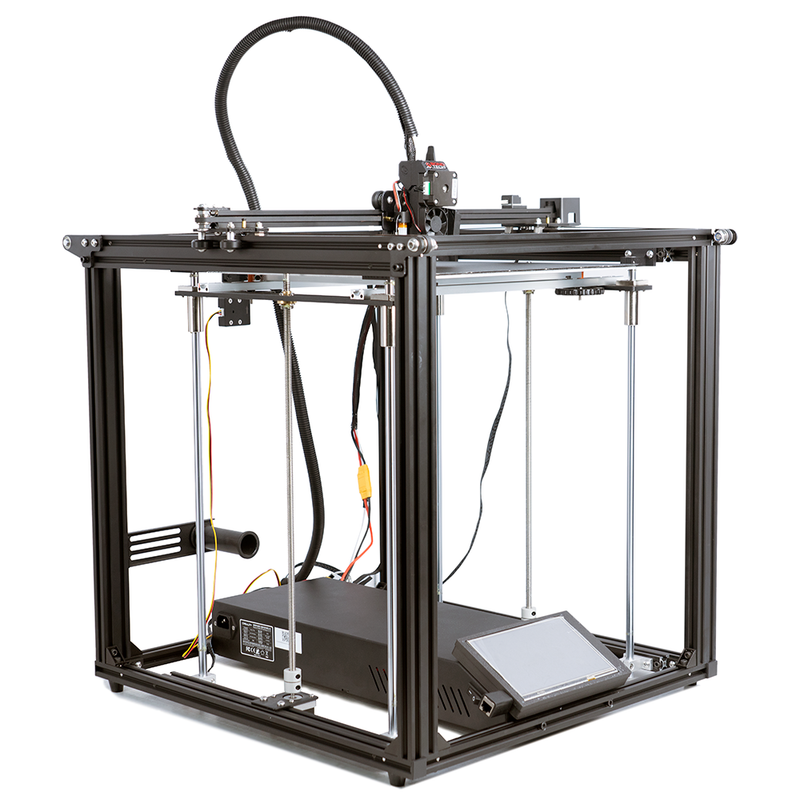

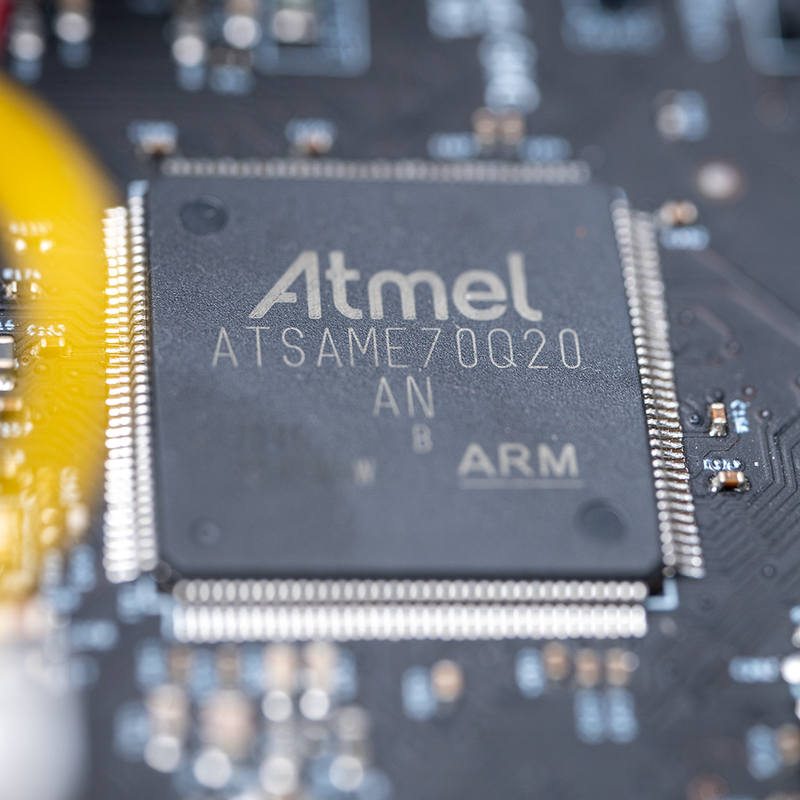

We took large scale printer base of a Creality Ender 5 Plus, and stripped it down and rebuilt it with a host of features and improvements, so you can print faster and longer, with minimal maintenance. The biggest design improvements were switching to BondTech dual drive extruder, high quality Slice Engineering parts and moreover adding a Duet3 6HC Mainboard with 32 bit processing.

Technical Specifications: Ender-5 Plus FDM 3D Printer Properties

- Modeling Technology: FDM(Fused Deposition Modeling)

- Printing Size: 350x350x400mm

- Chassis Size : 632x666x619mm

- N.W. : 18.2KG

- Power Parameters: Input: 100-240V AC; Output: DC 24V 21A; Max 25A;

- Print Accuracy: ±0.1mm

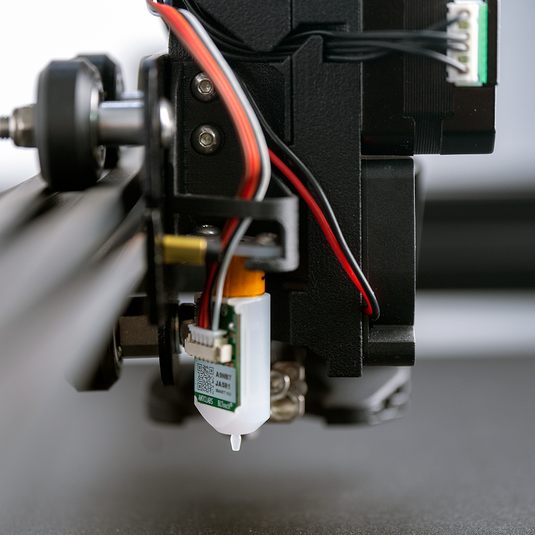

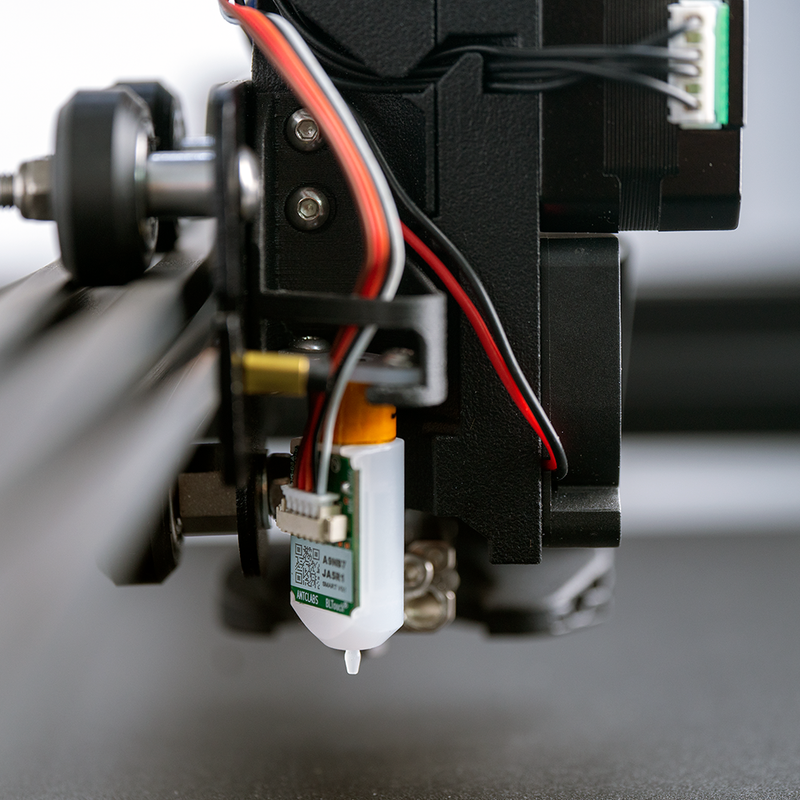

- BL Touch Bed leveling sensor

- Filament Sensor for filament run out detection

Upgrades added by ThinkRobotics:

- Enclosure to maintain uniform temperature around the build platform.

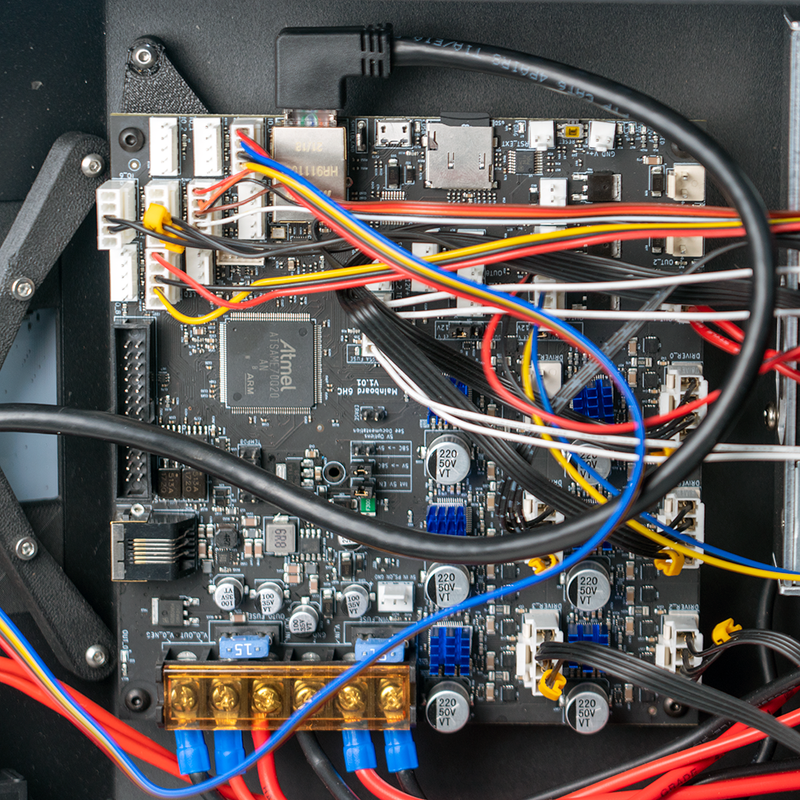

- Duet 3 6HC Clone Mainboard with 7" PanelDue and a custom configuration build to take full use of the 32bit processor on board.

- Heated Print Bed options included - standard glass bed or BuildTak FlexPlate System.

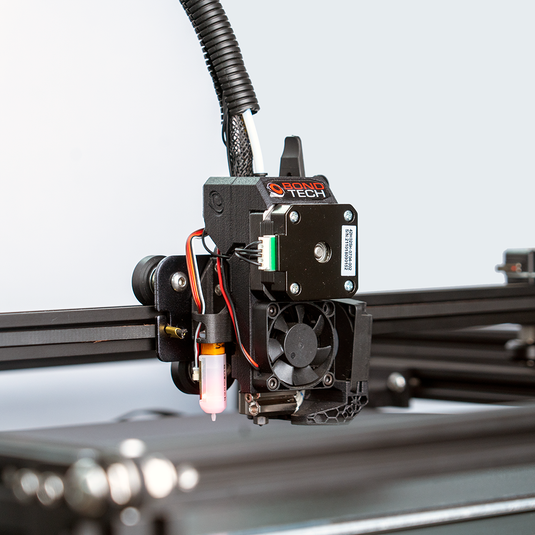

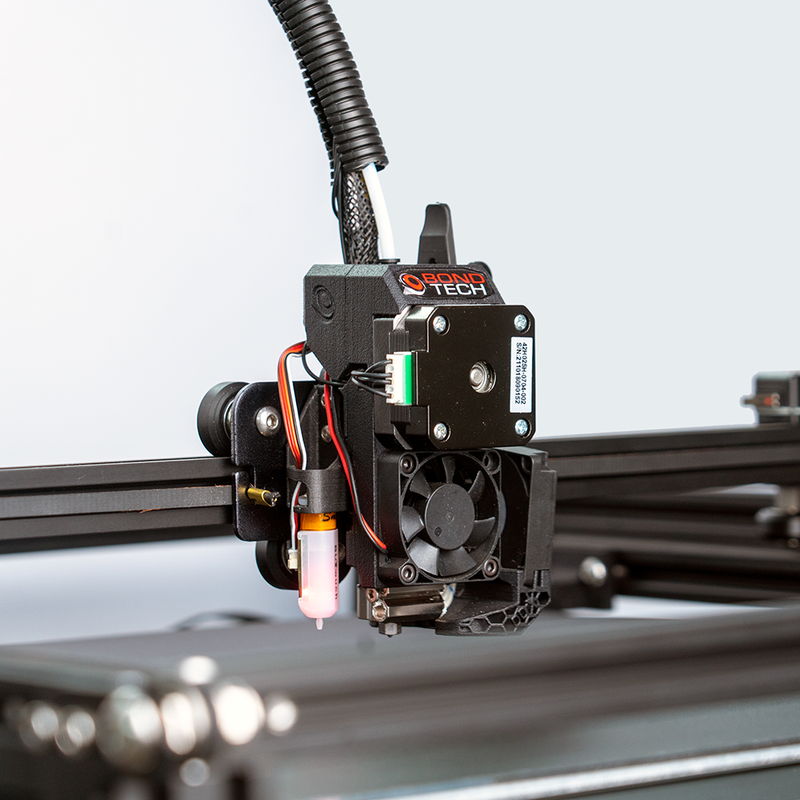

- Upgraded Extruder

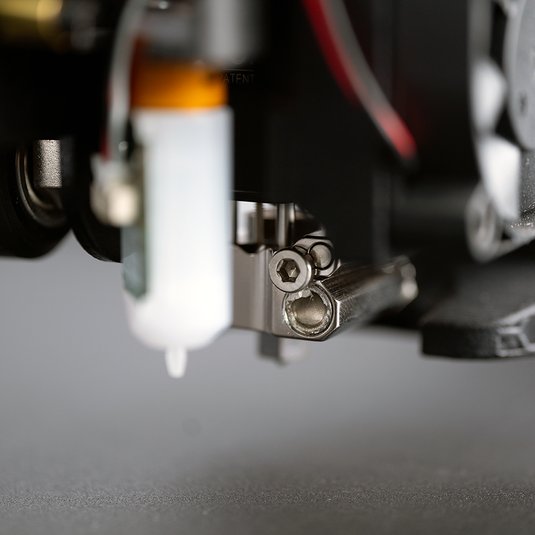

- Bondtech DDX v3 - Mini Geared extruder featuring higher gear ratio 3:1 that allows for extra push force and higher resolution

- Faster or higher print quality

- Decrease the risk of heat creep to avoid clogs and improve filament feeding by avoiding slipping and deformation that cause under and over extrusion issues

- Upgraded Hotend Fan for better airflow.

-

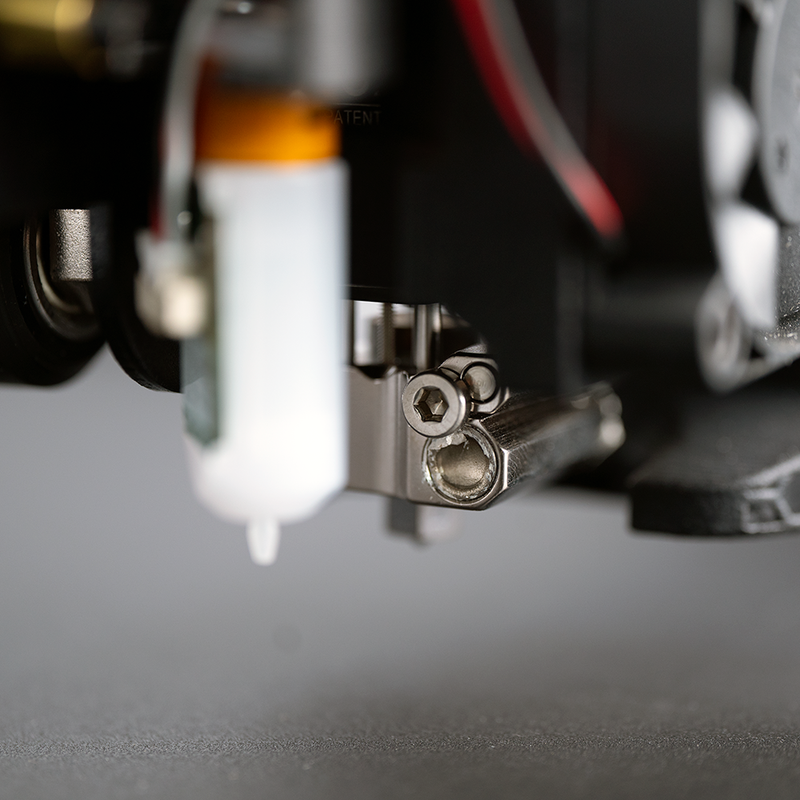

Hotend options include - Slice Engineering Mosquito Hotend, Slice Engineering: Mosquito® Magnum Professional Hotend or Copperhead™ Hotend

- 50W Slice Engineering Industrial Heater Cartridge

-

Slice Engineering High Temperature Thermistor - 300℃

-

Plastic Repellent painted hotend and nozzle.

-

Vanadium Nozzle for printing abrasive materials (0.4mm)

-

Torque Wrench for easy replacement of nozzles.

- External Spool Dispenser - eSun Filament Dryer/Dispenser

- Material Capability includes (but not limited to): Carbon Fibre reinforced Nylon, Carbon Fibre reinforced Polycarbonate, Fibre Glass reinforced Nylon, TPU, Polycarbonate, Nylon, Steelfill and woodfill PLA, ABS, PLA, ASA, HIPS, Polypropylene [materials not included]

Since, these are highly customized machines, we only offer remote/online support. Hands-on experience is highly recommended before buying this upgraded machine.

Want to buy in bulk?

Custom Requirements?

Discussion Forum

Feel free to ask questions, share tips or report issues.