The battle for dominance in the high-speed 3D printing market has intensified, with two standout contenders leading the charge: the Bambu Lab P1S and the Creality K1. Both printers promise lightning-fast printing speeds, CoreXY motion systems, and professional-grade features at competitive price points. But which one deserves a spot on your desk?

In this comprehensive comparison, we'll examine everything from build quality and printing performance to software capabilities and overall value. Whether you're a hobbyist looking to upgrade or a professional seeking reliable production capabilities, this guide will help you make an informed decision.

Quick Comparison Overview

Before diving deep, here's a snapshot of how these printers stack up:

|

Feature |

Bambu Lab P1S |

Creality K1 |

|

Price |

$699 (standalone) |

$389-$599 |

|

Build Volume |

256 × 256 × 256 mm |

220 × 220 × 250 mm |

|

Max Speed |

500 mm/s |

600 mm/s |

|

Enclosure |

Fully enclosed |

Fully enclosed |

|

Auto-leveling |

Yes |

Yes |

|

Multi-color |

AMS compatible |

CFS compatible |

Design and Build Quality: Premium vs Value

Bambu Lab P1S Construction

The P1S features a welded steel frame with plastic enclosure panels rather than aluminum, positioning it as the budget-friendly option in Bambu Lab's lineup while maintaining the premium feel the brand is known for. The printer weighs 12.9 kg, reflecting its solid construction and enclosed design.

The P1S comes with enhanced cooling solutions including an Auxiliary Part Cooling Fan, Chamber Regulator Fan for temperature control, and an activated carbon filter for odor management. This comprehensive cooling system enables consistent printing with engineering-grade materials like ABS and ASA.

Creality K1 Construction

The K1 is built with rigid die-cast aluminum alloy parts in its frame, enabling steady printing at high speeds while maintaining excellent print quality throughout the process. Despite its robust construction, Creality has managed to keep the K1 compact compared to other FDM printers with similar build volumes.

The K1 incorporates smart Creality OS with a straightforward UI that syncs seamlessly with PC, phone, cloud, and add-on modules. A dual-core 1.2GHz CPU powers high-speed printing operations, while 8GB ROM stores up to 400 model files for quick access.

Performance and Speed: Where the Magic Happens

Print Speed Capabilities

The Creality K1 achieves a maximum speed of 600mm/s with 20,000mm/s² acceleration, ramping up to full speed in just 0.03 seconds and delivering full speed operation for 90% of printing time. However, real-world speeds typically average around 300mm/s, with the 600mm/s achieved in laboratory conditions using 0.1mm layer heights.

The Bambu Lab P1S prints at a top speed of 500mm/s with acceleration from zero to 500mm/s taking just 0.025 seconds. While slightly slower on paper, even with a Bambu Lab P1S, you can consistently achieve 150-300mm/s with virtually no compromise in quality.

Motion System Technology

Both printers utilize the CoreXY kinematic motion system that pairs X and Y axes controlled by two synchronized stepper motors, while the Z-axis is controlled by three lead screws for stability. This design removes print bed movements along the Y-axis, creating an extremely stable printing experience.

The K1 combines nimble CoreXY mechanics with a lightweight 190g printhead for reduced motion inertia, contributing to its agile and swift performance. A G-sensor in the printhead measures resonance frequencies during high-speed printing and auto-tunes the printer to mitigate ghosting and ringing effects.

Build Volume and Print Capabilities

Print Area Comparison

The Bambu Lab P1S offers a slightly larger build volume at 256 × 256 × 256 mm (10.1" × 10.1" × 10.1"), providing a perfect cubic printing space. The Creality K1 features 220 × 220 × 250 mm (8.6" × 8.6" × 9.8") build dimensions.

While the P1S can print slightly larger objects than the K1, the difference is small enough that most users may not notice the limitation in day-to-day use.

Material Compatibility

Both printers feature direct-drive extruders with dual-gear systems that grip filament on both sides for increased extrusion force and reliability. Both can handle flexible materials like TPU more effectively than Bowden extruders.

Both machines include all-metal hotends capable of reaching 300°C, hot enough for all common 3D printing filament types, including high-temperature materials like nylon. The K1C variant adds carbon fiber printing capabilities, though this requires the upgraded model.

Software and User Experience

Bambu Lab Ecosystem

The P1S syncs seamlessly with Bambu Lab's proprietary slicing software – Bambu Studio, and offers additional capabilities for remote monitoring and time-lapse recordings through their mobile app, Bambu Handy.

The printer's highly sensitive auto bed leveling system creates perfect first layers without any manual adjustment needed. After a few minutes of auto calibration, the printer simply works.

Creality Software Solutions

The K1 series utilizes Creality's Print 4.3 software, incorporating advanced algorithms to optimize efficiency and offering optimized nozzle movement for faster prints. The K1 Max variant features dual hands-free auto leveling, using both strain sensors and 1μm AI LiDAR for rapid, precise surface scanning.

K1 supports printing via USB drive or data-secure LAN, with WiFi connectivity enabling remote control and monitoring through Creality Print or Creality Cloud apps. Cluster control is available when multiple K1 printers are online.

Multi-Color Printing Options

Bambu Lab AMS System

All Bambu Lab printers support the AMS (Automatic Material System), which can swap between 4 materials during a print. You can connect up to 4 AMS units together for 16-material capability on X and P-series printers. The AMS stands out for its maturity and reliability, having been tested across various printer models with seamless integration into the Bambu ecosystem.

Creality CFS System

Creality offers the CFS (Color Filament System) as their answer to multi-material printing. While newer and less tested than the Bambu AMS, it provides a potentially more affordable option with integration designed specifically for Creality printers. Recent developments show the K1-Series getting CFS compatibility, with Creality announcing adaptation kits for existing K1, K1C, and K1 Max printers.

Pricing and Value Proposition

Bambu Lab P1S Pricing

The Bambu Lab P1S typically retails for $899 MSRP, though frequent sales bring it down to $699. The P1S kit includes the printer, hotend, build plate, PLA filament spool, unclogging pin, and accessory box. It can be purchased with the AMS included in a combo package or separately, with pricing ranging from $699 to $995 depending on configuration.

Creality K1 Pricing

The standard Creality K1 is available for approximately $389, while the K1 SE variant costs around $359, representing a $30 savings for those willing to accept open-source flexibility over plug-and-play convenience. When considering discount codes and MSRP, the Creality K1 price point sits lower than the P1S.

Reliability and Support

Track Record Comparison

Bambu Lab offers a more proven product with a better track record of simply working out of the box, plus the option for AMS multi-material system integration. Bambu Lab has been working on their technology for more than two years and has industry luminaries in software and motion control on their team.

While Creality has made significant leaps forward in hardware and software with the K1 series, the machines still don't fully exploit their potential, mainly due to immature slicer software and firmware compared to Bambu's offerings.

Customer Support

Some Creality K1 users report challenges with customer service and support, with mixed experiences in warranty situations and technical assistance. Bambu Lab generally receives higher marks for customer support responsiveness and problem resolution.

Which Printer Should You Choose?

Choose the Bambu Lab P1S if:

-

Print quality is paramount: You want consistent, reliable results with minimal tinkering

-

Multi-material printing: You plan to use the AMS system for complex, multi-color projects

-

Professional use: You need a dependable workhorse for business applications

-

Software integration matters: You value seamless software experience and regular updates

-

Time is valuable: You prefer plug-and-play operation over troubleshooting

Choose the Creality K1 if:

-

Budget is primary concern: You want high-speed CoreXY performance at the lowest price point

-

Tinkering appeals to you: You enjoy customizing and optimizing your printer

-

Speed is everything: You prioritize maximum print speeds over other considerations

-

Open-source preference: You value the ability to modify firmware and settings

-

Larger projects: You're considering the K1 Max for significantly larger build volumes

Final Verdict

The recommendation still leans toward the Bambu Lab P1S over the Creality K1 when weighing print quality, support, and overall machine track record, despite the higher price point. The P1S offers a more mature ecosystem, proven reliability, and superior out-of-box experience.

However, the Creality K1 represents exceptional value for users willing to invest time in optimization and learning. For those needing larger print volumes beyond 250 × 250 × 250 mm, Creality's K1 Max becomes the clear choice, as Bambu Lab doesn't currently offer competing large-format options.

Both printers represent significant advances in affordable high-speed 3D printing technology. Your choice ultimately depends on whether you prioritize proven reliability and ease of use (P1S) or maximum value and customization potential (K1).

Frequently Asked Questions

Q1: Can I upgrade the Creality K1 to match P1S capabilities?

A: While the K1 offers open-source firmware that allows extensive customization, achieving P1S-level reliability and software integration requires significant technical knowledge and aftermarket modifications. The fundamental hardware differences in motion control and sensor systems cannot be easily bridged through upgrades alone.

Q2: How does maintenance differ between these printers?

A: The Bambu Lab P1S requires minimal maintenance due to its enclosed design and automated systems, with main tasks being nozzle cleaning and occasional calibration checks. The Creality K1 may require more frequent adjustments and troubleshooting, particularly with bed leveling consistency and extruder performance, though this varies by individual unit quality.

Q3: Which printer handles flexible filaments better?

A: Both printers feature direct-drive extruders that handle flexible materials like TPU well. However, the P1S typically provides more consistent results with flexible filaments due to its superior motion control algorithms and pressure advance technology, while the K1 may require more tuning for optimal flexible filament performance.

Q4: Are there significant differences in noise levels during operation?

A: The enclosed design of both printers helps reduce noise, but the P1S generally operates more quietly due to its advanced vibration compensation and motion smoothing algorithms. The K1 can be noisier during rapid movements and acceleration phases, though both are significantly quieter than traditional bed-slinger designs.

Q: How do software updates and long-term support compare? A: Bambu Lab provides regular OTA (over-the-air) firmware updates and has a more established update schedule with new features and improvements. Creality's update cycle is less predictable, though the open-source nature of the K1 allows community-driven firmware development. For long-term support, Bambu Lab currently offers more comprehensive manufacturer backing.

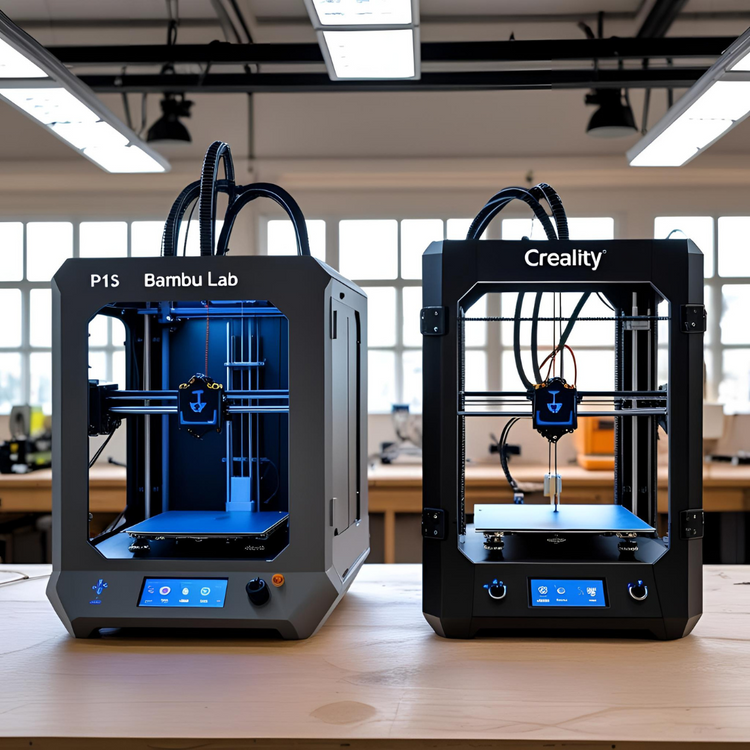

AI generated photo and most likely ai gernerated post.

AI photo???

I don’t know about everyone else, but the P1S I know looks very different to your picture. That picture is just the same two machine with Bambu Lab stenciled on one of them. Chinese knock off of a Chinese printer I guess.

We’re supposed to believe you in your article on this when your headline photo isn’t even of the machines you’re talking about?