3DXSTAT™ ESD-Safe Polycarbonate (ESD PC) 3D Printing Filament

3DXSTAT ESD PC is an advanced ESD-Safe compound designed for use in critical applications which require electrostatic discharge (ESD) protection. Made using cutting-edge multi-wall carbon nanotube technology, state of the art compounding technology, and precision extrusion processes. Target surface resistance of 10^7 to 10^9 Ohm.

Benefits of 3DXSTAT ESD-PC

High thermal properties including a Tg of 147°C

Amorphous structure gives low, near isotropic shrinkage

Excellent ductility and impact resistance

Very low odor emitted while printing

Wide processing range of 265-300°C

Benefits of 3DXSTAT™ Include

Consistent surface resistivity

Improved retention of impact & elongation

Low particulate contamination

Minimal contribution to outgassing and ionic contamination

This product contains 1000 grams of filament.

2.85mm Available on order only. (Lead time: <7 days)

Typical ESD PC Applications Include

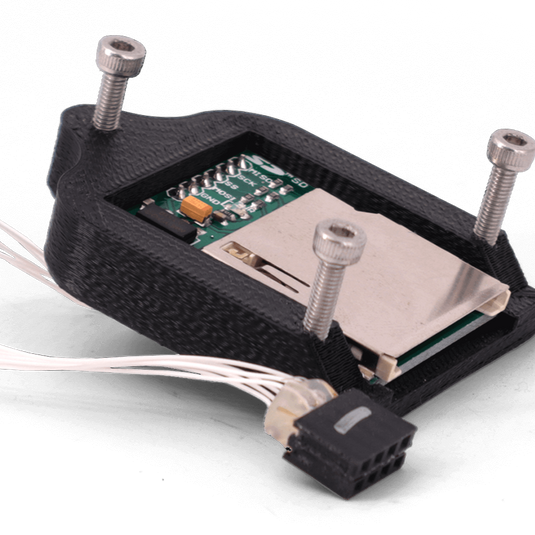

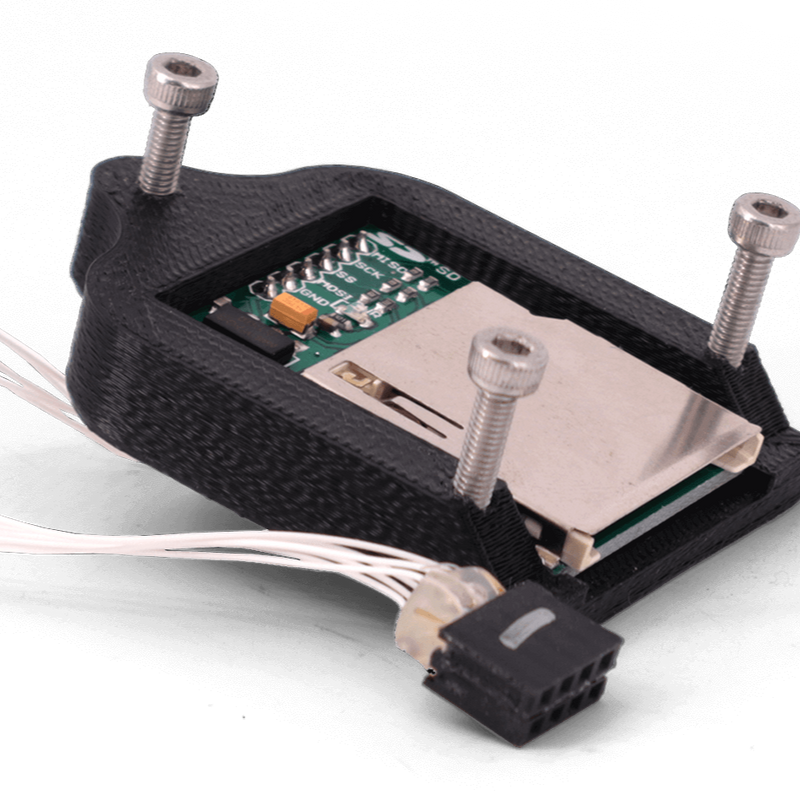

Semi-con: HDD Components, Wafer Handling, Jigs, Casings, & Connectors

Industrial: Conveying, Metering, and Sensing Applications

Target Conductivity for 3DXSTAT ESD PC

10^7 to 10^9-ohm surface resistivity on 3DP sample using concentric ring test method.

Note: Internal studies have indicated that increased extruder temperatures can achieve higher levels of conductivity. Likewise, lower extruder temperatures have resulted in lower levels of conductivity. Each printer is set up differently as well as varied part geometry. Therefore, expect some trial time to understand how ESD PLA filament works in your specific printer/application.

Surface Conductivity as a Function of Extruder Temperature

The surface resistance of the printed ESD PC part will vary depending on the printer’s extruder temperature. For example, if your testing indicates the part is too insulative, then increasing the extruder temperature will result in improved conductivity. Therefore, the surface resistance can be ‘dialed-in’ by adjusting the extruder temperature up or down depending on the reading you receive on your part.

Specifications

1.75mm and 2.85mm +/- 0.05mm in diameter

Recommended Print Settings:

Extruder: 260-300°C

Bed Temp: 110-120°C

Bed Prep: Magigoo Bed Prep or 3DXTECH Polyimide Tape gives us the best results

Heated Chamber: Recommended, a chamber helps reduce warping and improves layer adhesion

Supports: AquaTek™ water soluble X1 USM Universal Support Material works ideal for complex parts

Drying Instructions: 120°C for 4 hours.

New Digital Catalog

Packed with your favorite products, detailed information, and essential technical data. Whether your brand new to 3-D printing or need to find a specific filament that best fits your project, our catalog has everything you need in one easy-to-navigate place!

Product Performance Comparison

Explore key attributes like tensile strength, flexural strength, glass transition, and fire testing performance. Whether you're prototyping, creating functional parts, or printing detailed models, these property graphs will help you find the perfect filament for your project.

Want to buy in bulk?

Custom Requirements?

Discussion Forum

Feel free to ask questions, share tips or report issues.