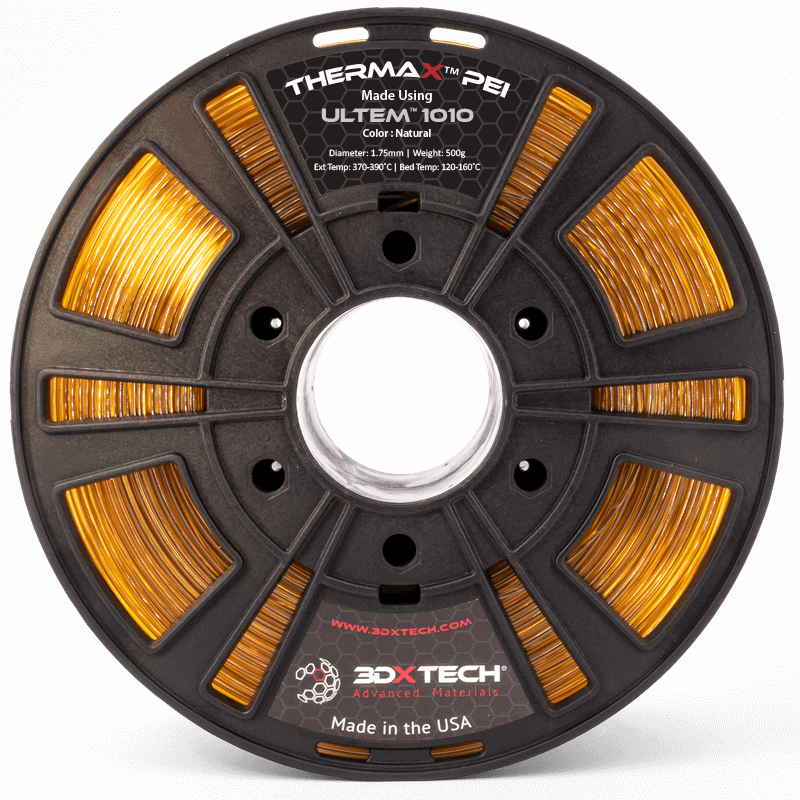

ThermaX PEI 1010

3DXTECH produces this 3D printing filament using a specialty compound custom-formulated using ULTEM 1010 PEI resin and advanced carbon additives. PEI is an amorphous, high-performance polymer that combines excellent mechanical, thermal, and chemical resistance properties.

Our PEI based filaments offer the ability to create parts with excellent properties at elevated temperatures due to a very high glass transition temperature (Tg). Ideal for use in critical applications which require electrostatic discharge (ESD) protection, a high level of cleanliness, and the outstanding thermal and chemical properties you’ve come to expect with PEI based compounds.

Benefits of ULTEM 1010 PEI Include

High thermal properties, with a Tg of 217°C

Inherently flame-resistant

Long-term hydrolytic stability

Excellent dimensional stability, low heat creep sensitivity, and a very low, uniform coefficient of thermal expansion creates highly reproducible part-to-part dimensions

Exceptional strength and modulus, even at elevated temperatures

Good resistance to a broad range of chemicals includes automotive fluids, fully halogenated hydrocarbons, alcohols, and aqueous solutions

Stable dielectric constant and dissipation factor over a wide range of temperatures and frequencies

ULTEM 1010 PEI Applications

Aerospace: The excellent balance of flame retardancy, low smoke emission, and low smoke toxicity of ULTEM™ 1010 makes it an excellent candidate for aerospace and aircraft applications. ULTEM 1010 meets FAR 25.853 and OSU 65/65 with low toxicity, smoke, and flame evolution. Ultem™ resins are found in applications such as personal service units, oxygen panels and components, ventilation system components, connectors, cable ducts, latches, hinges, food tray containers, door handles, and interior cladding parts.

Automotive & Transportation: ULTEM™ resins provide automotive manufacturers with a high-performance, chemically resistant, thermally stable, cost-effective alternative to metal that is strong enough to replace steel in some applications yet light enough to replace aluminum in others. For applications like transmission components, throttle bodies, ignition components, sensors, and thermostat housings.

Electronics: ULTEM™ resin may be an excellent material choice for today’s demanding electrical applications, including connectors, MCB components like housings, shafts and levers, hard disk drive internals, FOUPs, BiTS, PCBs, MCCB internals, Plenum devices, LCD projector internals, fuel cell components, and many other applications.

Specifications

1.75mm and 2.85mm +/- 0.05mm in diameter

Print Recommendations

Extruder: 370-390°C

Bed Temp: 120-160°C

Bed Prep: Nano Polymer Adhesive or 3DXTECH Polyimide Tape gives us the best results

Other: No cooling fan with print speeds of 20mm/s as a starting point

Heated Chamber: Recommended, a chamber helps reduce warping and improves layer adhesion

Supports: ThermaX HTS High-Temp Support works ideal for complex, high-temp materials just like this.

Drying Instructions: 120°C for 4 hours.

Annealing 3D Printed Parts

If needed, parts printed using ULTEM™ may be annealed in a hot-air oven to reduce any printed-in stresses which may be present in the part. Printed-in stresses may occur in any plastic and may result in lower than expected mechanical properties. If this is an issue with your part, you can follow the simple 5-step ramp up/down process for annealing the ULTEM™ parts.

Step 1: Place printed parts in a cool, room-temp oven.

Step 2. Set temp to 300°F and allow to stabilize for 1 hour.

Step 3: After 1 hour at 300°F, increase oven temp to 400°F and allow to stabilize 1 additional hour.

Step 4: After 1 hour at 400°F, reduce heat back to 300°F and allow to stabilize for 30 minutes.

Step 5: After 30 minutes, turn off oven heat and allow printed parts to return to room temp inside the oven as it cools.

New Digital Catalog

Packed with your favorite products, detailed information, and essential technical data. Whether your brand new to 3-D printing or need to find a specific filament that best fits your project, our catalog has everything you need in one easy-to-navigate place!

Product Performance Comparison

Explore key attributes like tensile strength, flexural strength, glass transition, and fire testing performance. Whether you're prototyping, creating functional parts, or printing detailed models, these property graphs will help you find the perfect filament for your project.

Resources

Want to buy in bulk?

Custom Requirements?

Discussion Forum

Feel free to ask questions, share tips or report issues.